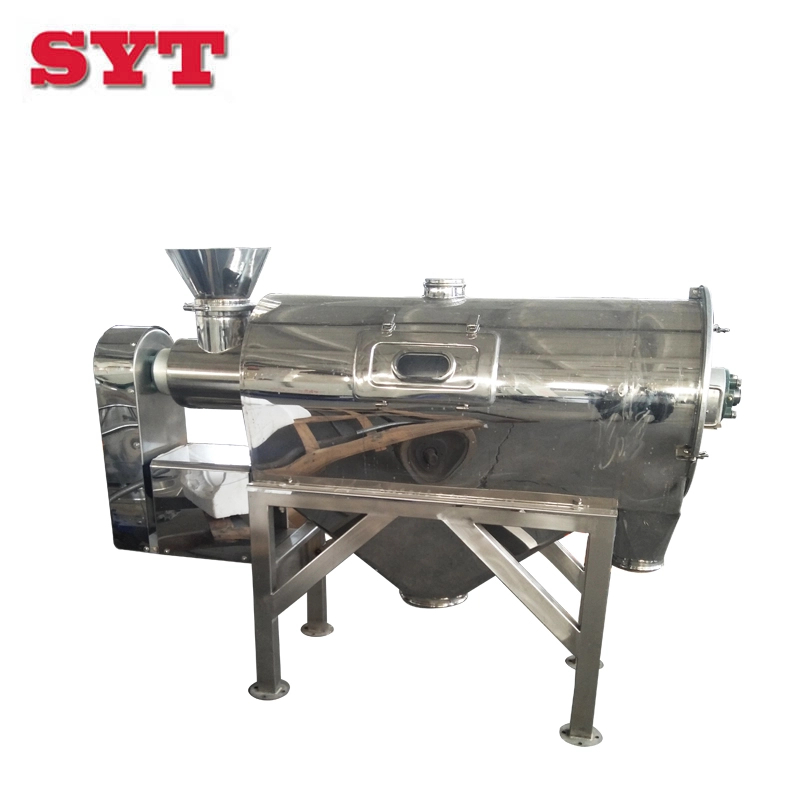

The screen of the airflow sieving machine is cylindrical, placed in the body, the material is through the spiral conveying system and airflow mixing, atomization into the mesh cylinder, through the mesh cylinder wind wheel blades so that the material is subjected to centrifugal force and cyclone propulsion force at the same time, so that the material jet over the net, over the net from the fine material discharge outlet discharge, can not be over the net of material along the cylinder wall from the coarse material discharge outlet discharge, to achieve the purpose of high-efficiency separation.

According to the screening materials, different industries, different materials, mainly 304 stainless steel, carbon steel, and so on.

- Model: WQS18-85/WQS30-100/WQ70-180/WQ50-130

- Material: Stainless Steel 304

- Mesh Size: 5-500 mesh

- Voltage: 220V/380V/415V/450V

- Capacity: 100Kg-5tons/hour

- Customized: Acceptable

Price: $2250 – $5900 /Set

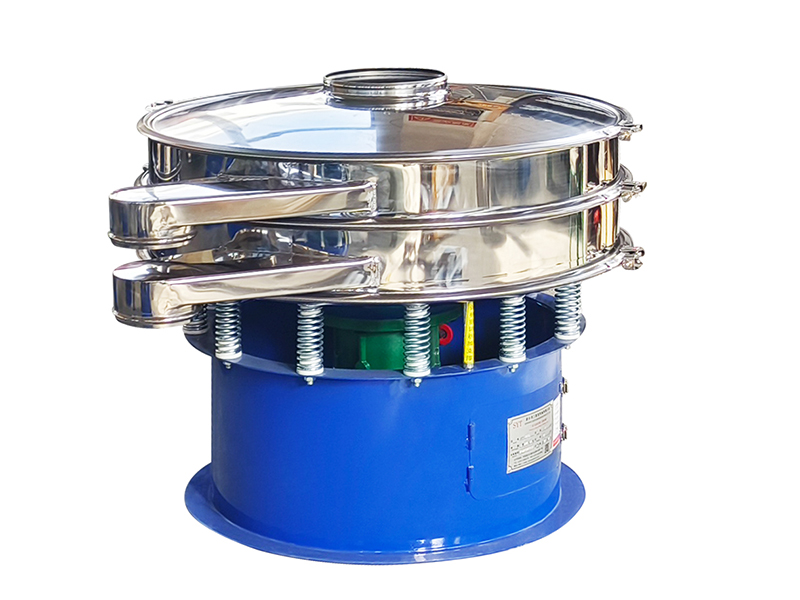

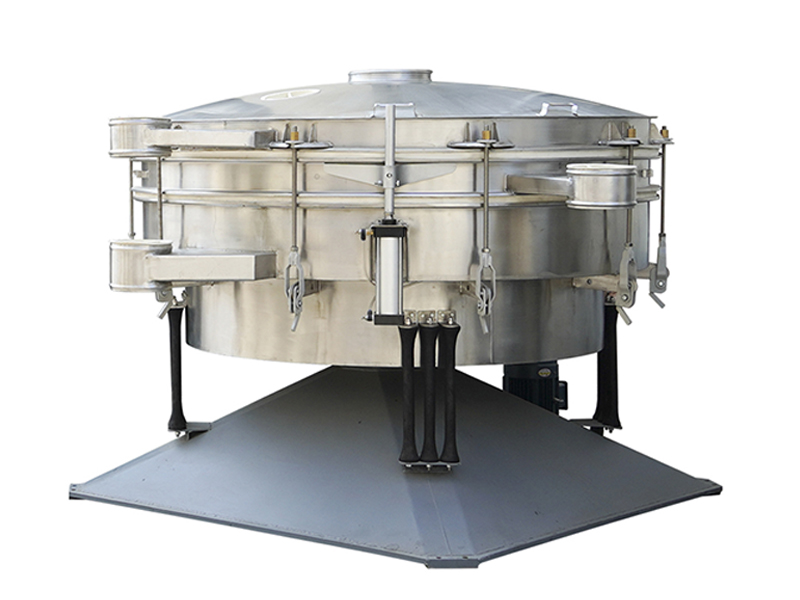

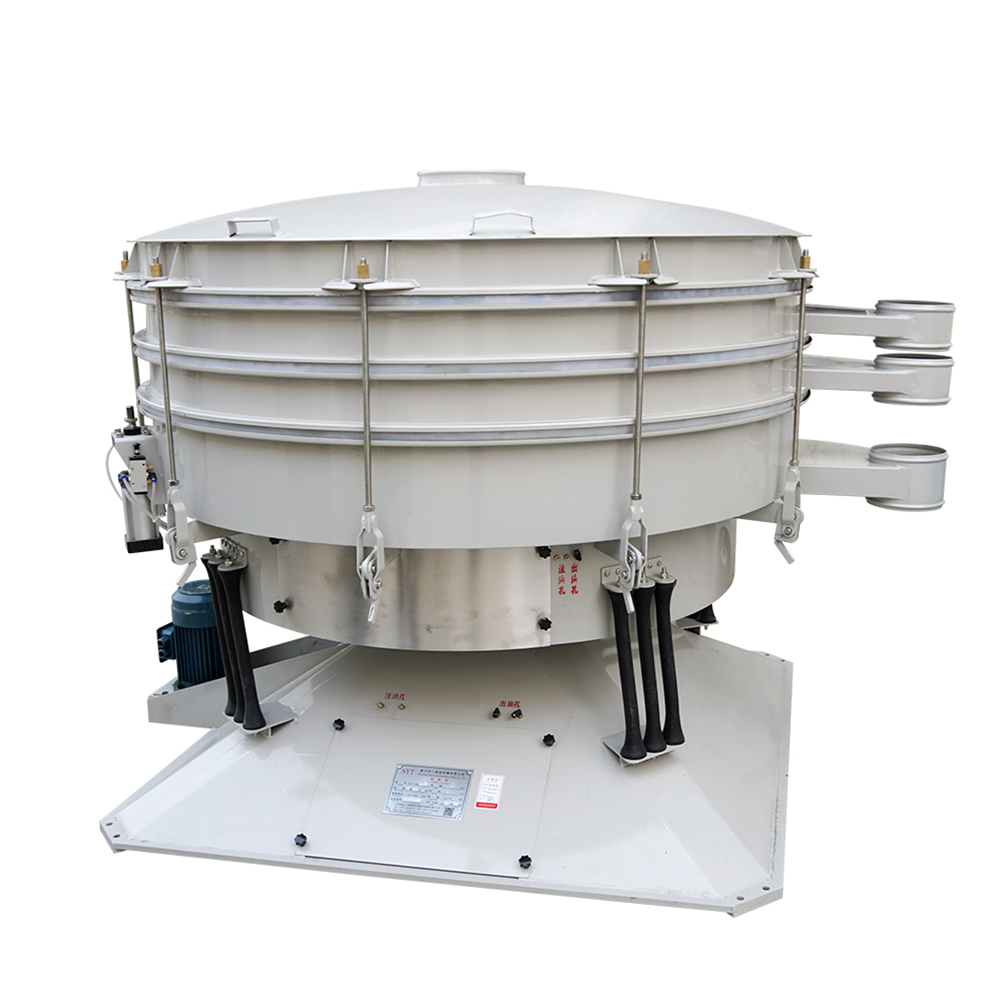

Application

Airflow sieve machine is used in metallurgy, mining, pharmaceutical, food, chemical industry, metal powder, and nonmetal, etc.

Airflow screen is widely used in all kinds of fine powder which is difficult to screen, fine powder in the range of 50-500mesh can be very well screened. Such as light calcium powder, active calcium powder, active carbon powder, starch, medicine powder, fly ash, zinc powder, graphite powder, quartz sand powder, gold powder, pottery clay powder, hawthorn powder, fruit thinning powder, calcium hydroxide powder, pesticide powder, konjac powder, fluorescent powder, wood powder, flour, epoxy resin powder, manganese dioxide, sulfur powder, alumina powder, bakelite powder, magnesium oxide, perlite powder, iron powder, cotton linters, etc.

Flour

Flour Milk Powder

Milk Powder Medicine Powder

Medicine Powder Paint

Paint Metal Powder

Metal Powder Sugar powder

Sugar powder Light calcium powder

Light calcium powder chemical powder

chemical powder