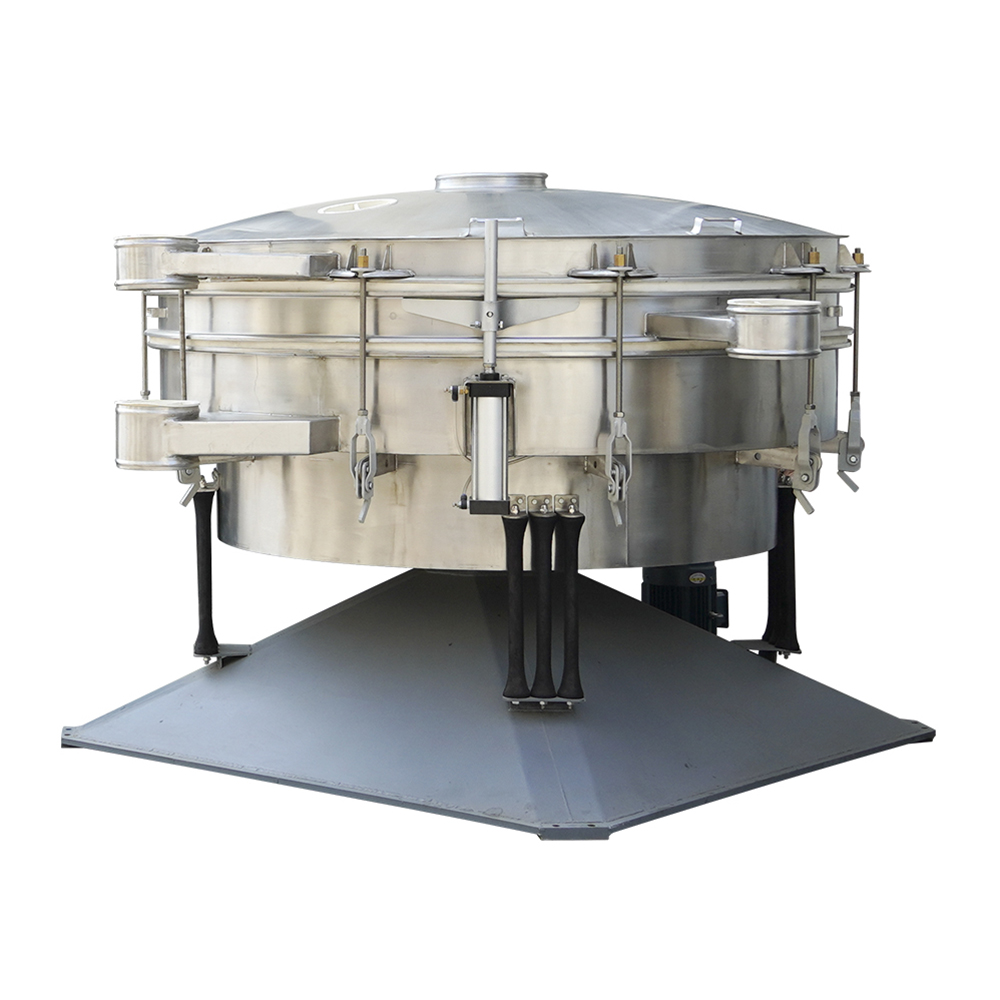

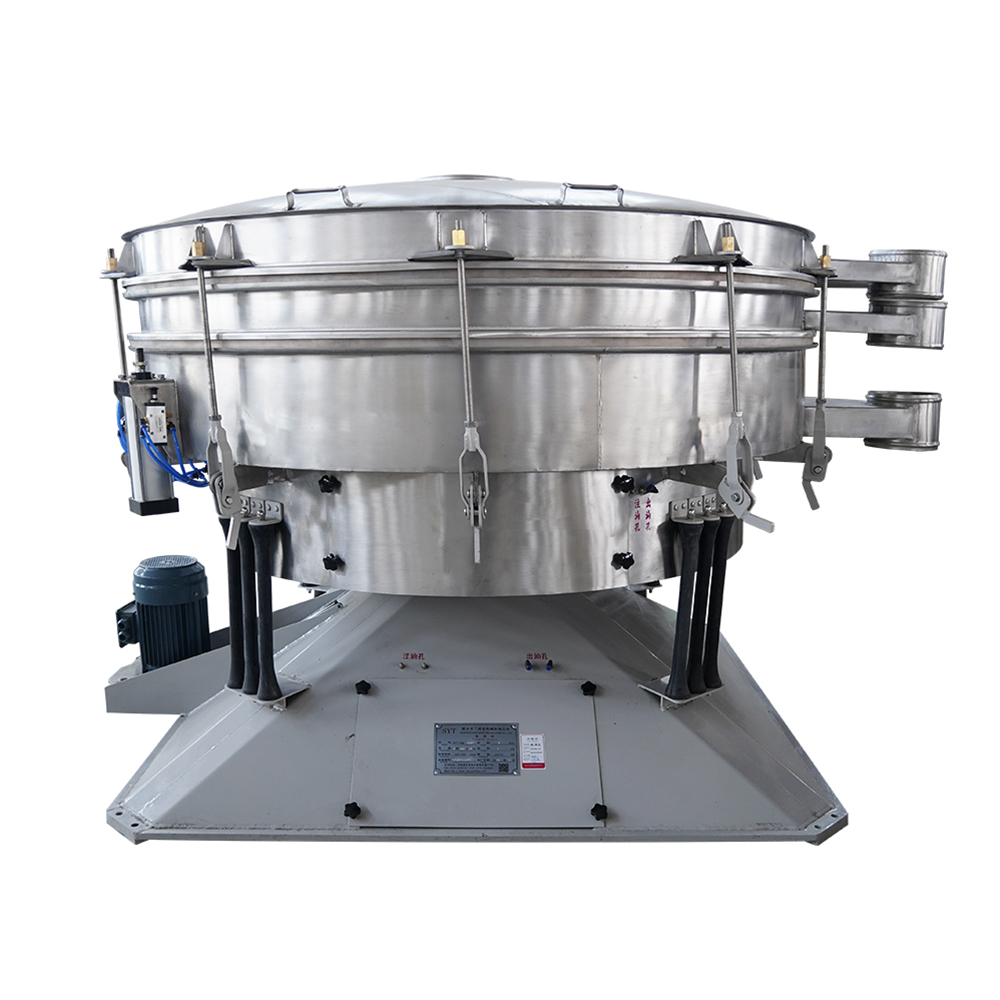

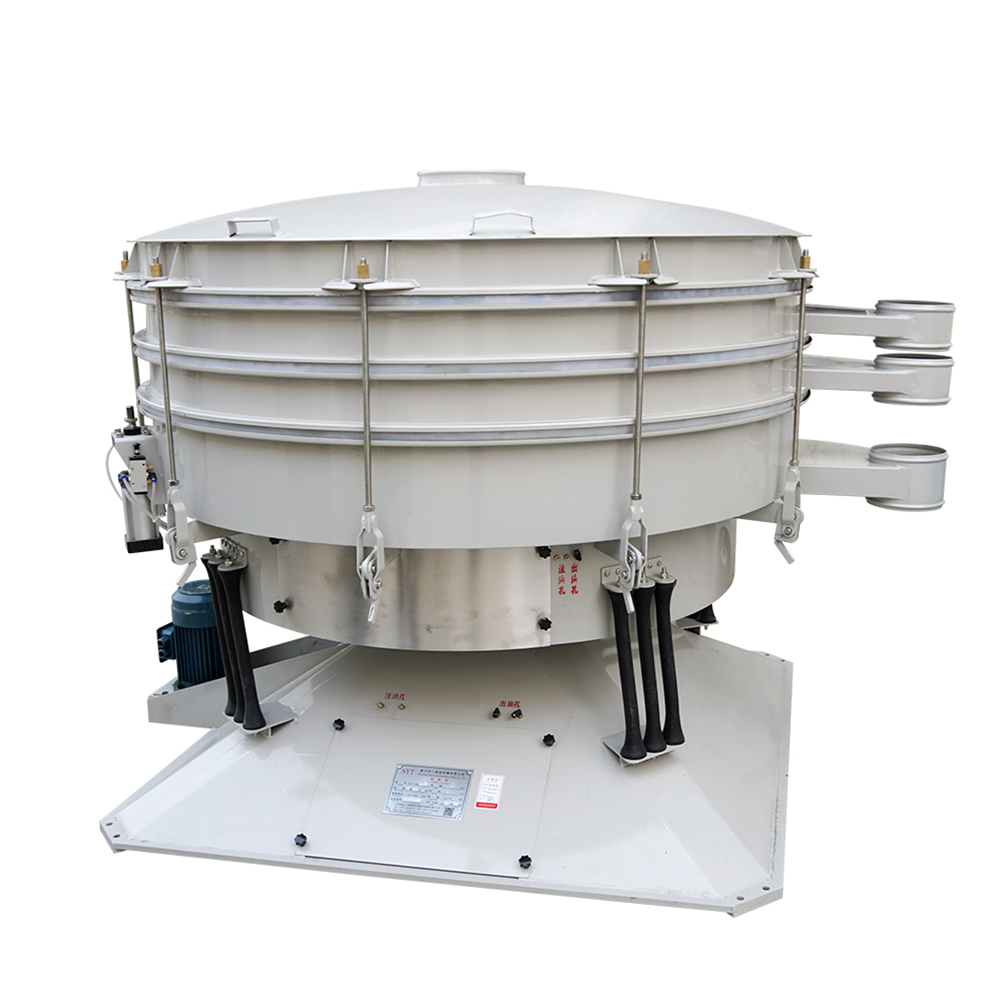

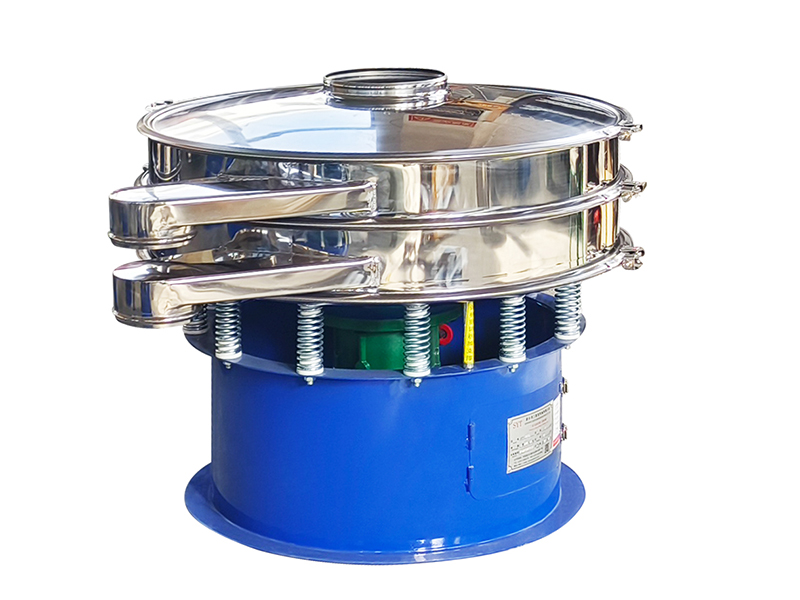

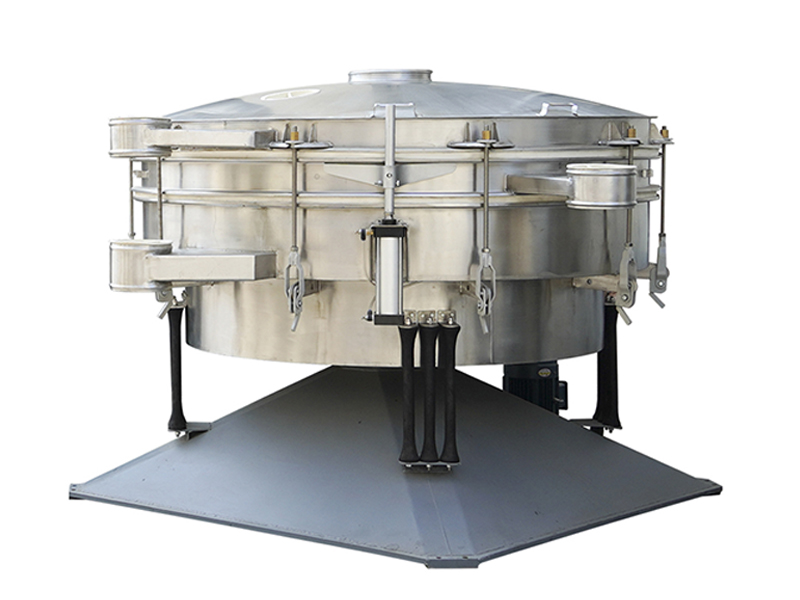

The design of the tumbler screen is a high-efficiency vibrating sieve machine specially designed to meet the needs of large-volume, higher-screening manufacturers. The simplest screening is to use both eyes to screen with both hands. Simulation is currently the most effective simulation of the effective principle of manual screening movement (screening accuracy, efficiency, and screen life are 5-10 times that of a conventional round screen), which meets all fine and ultra-fine powders and particles Shaped materials, especially suitable for difficult materials.

- Model: YBS-2600/2200/2000/1600/1200/1000

- Material: Carbon Steel/Stainless Steel 304/316L

- Mesh Size: 2-500 mesh

- Layers: 1-10 layers

- Motor Power: 5.5kW/7.5 kW

- Capacity: 500-4500 kg/h

- Customized: Acceptable

Price: $5,020.00 – $9,535.00 / Set

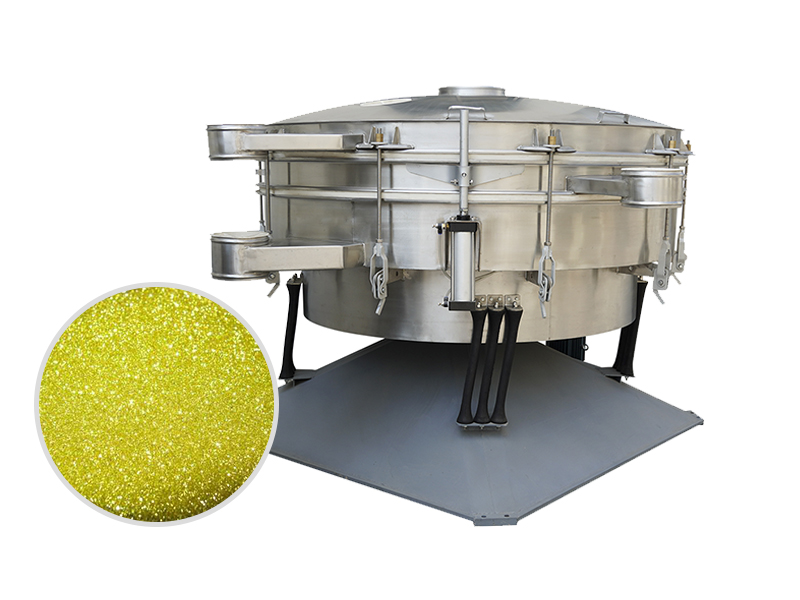

Application

- Chemical industry: resin, pigment, grease, fire retardant, rubber, plastic, etc.

- Abrasives, glass, and ceramic industries: silica sand, alumina, abrasives, glass powder.

- Food industry: sugar, salt, alkali, monosodium glutamate, starch, milk powder, soy milk, yeast

- Pharmaceutical industry: Chinese medicine powder, Western medicine powder, pharmaceutical raw materials.

- Ironmaking and mining: quartz sand, ore, titanium oxide, zinc oxide, and magnesium metal powder.

- Machinery industry: foundry sand, powder metallurgy, electromagnetic materials, aluminum powder, metal powder.

- Others: carbon black, activated carbon, pearls, coatings, cable materials

Spices

Spices Medicine Powder

Medicine Powder Sugar Powder

Sugar Powder Plastic particles

Plastic particles Paint

Paint Glass Powder

Glass Powder Metal Powder

Metal Powder Metal silicon powder

Metal silicon powder Calcium Carbonate

Calcium Carbonate

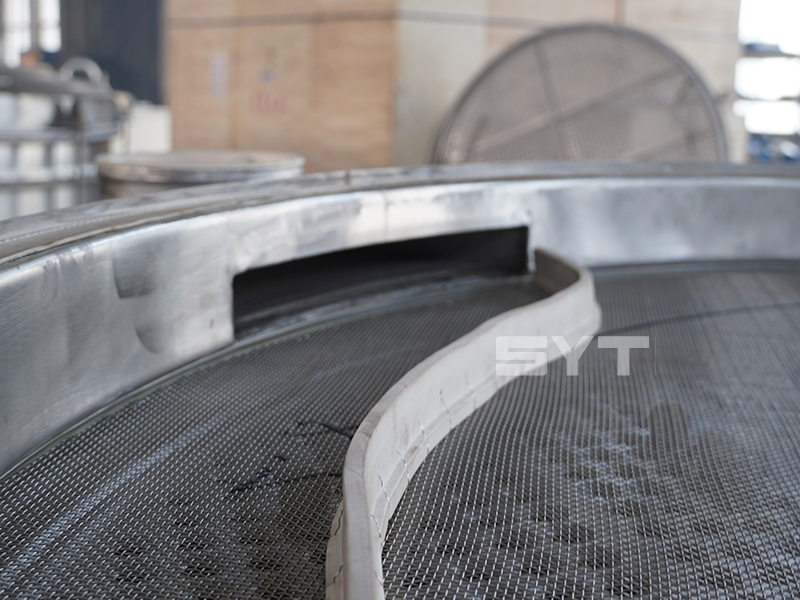

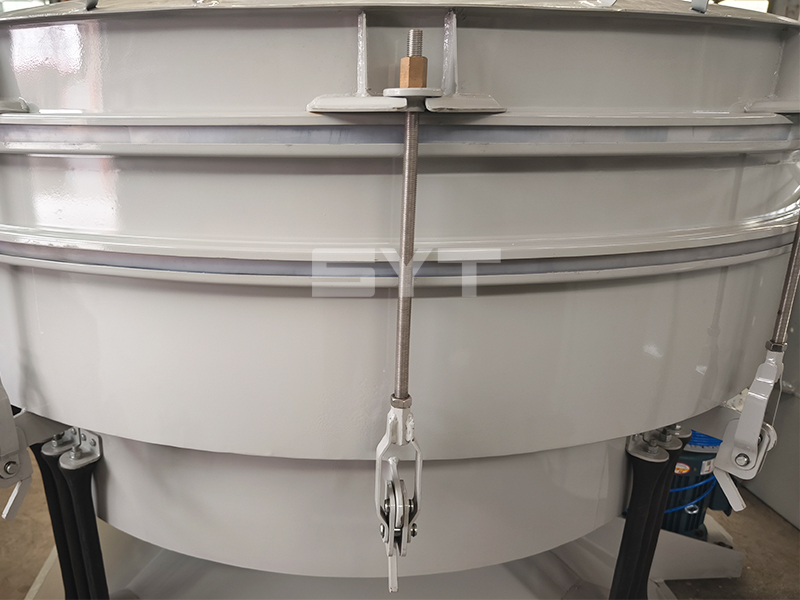

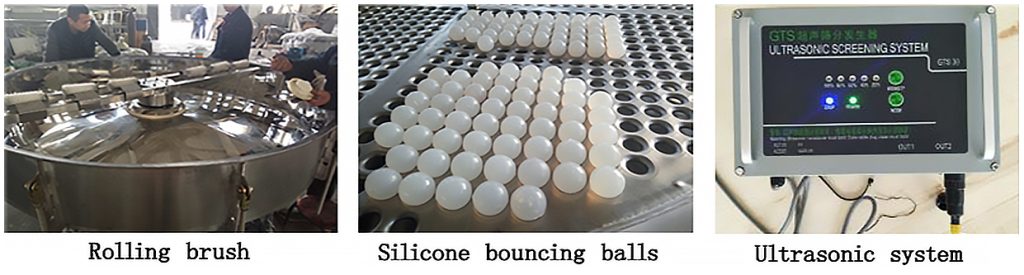

3 Types of Cleaning System

During the screening process of the circular tumbler screening machine, materials with strong adsorption, easy clumping, high static electricity, high fineness, high density, light specific gravity and other characteristics can easily block the mesh, thus greatly reducing the work efficiency and screening effect. Therefore, in order to ensure the screening effect, a screen cleaning device needs to be added to the equipment. The following are 3 types of screen cleaning system devices suitable for different material requirements. If you are not sure how to choose the screen cleaning method, please contact us to customize the best product solution for you.

1. Rotary brush cleaning

The rotary brush is driven by the reduction gear installed on the base chassis. It rotates and brushes under the screen to clean the materials. It is suitable for screening spherical, crystallized, and brittle materials.

2. Bouncing ball cleaning

Rubber and silicone balls bounce on the punching plate under the screen and bounce against the metal mesh to reduce mesh clogging. This system is simple to use and maintain and is suitable for most granular materials.

3. Ultrasonic cleaning

High-frequency ultrasonic waves are transmitted to the screen, which cleans the screen and improves production capacity. It is suitable for most fine, large-volume, and difficult-to-screen materials.

Material Movement Method:

The adjustment of the meridional and tangential angles can adjust the involute movement of the screen. This movement enables the material to travel a relatively long path on a small area to improve the screening accuracy. The unique design allows the material to be online The moving netting time is longer than other screen machines, and the screening output is relatively improved.

Features

- Up to 5 times the output per unit area.

- 2 to 6 stages of separation, with screening efficiency as high as 90%-99%.

- Optional network cleaning device system. The sieve holes are not easily blocked.

- Sealed dust removal, safe operation.

- The acceleration is 4.5 times lower than that of the vibrating screen. Improve the life of screening parts.

- Optimized and balanced, the dynamic load of the foundation is low.

Technical Parameters

| Model | Availability of screening area(m*m) | Screen slope (angel) | Grain size(mm) | Double amplitude(mm) | Power(kw) | Process capacity(t/h) |

|---|---|---|---|---|---|---|

| HXSY -1000 | 0.71 | 0-10 | ≦10 | 5-8 | 1.5 | 8-15 |

| HXSY -1200 | 1.11 | 5-8 | 2.2 | 15-30 | ||

| HXSY -1600 | 1.83 | 5-8 | 2.2/4 | 25-50 | ||

| HXSY -2000 | 2.62 | 5-8 | 2.2/4 | 30-60 | ||

| HXSY -2200 | 3.46 | 3/4 | 35-60 | |||

| HXSY -2600 | 5.31 | 5-8 | 5.5 | 45-60 |

Details Show

Advantages of Tumbler Screen

Fully enclosed structure

The dust does not fly, and the noise during operation is <75 decibels, which meets environmental protection requirements.

Imported high-quality motor

The vibration motor adopts a high-quality motor as the transmission source, imported technology, and the transmission method imitates manual screening.

Effectively protect materials

The soft rocking mode of screening can effectively protect the original shape of the material particles from being destroyed.

Meet different screening requirements

There are three motion modes: circular, elliptical, and linear, suitable for different material screening requirements.

Equipment operation is balanced and stable

The scientific and reasonable structure of the equipment is adopted to ensure a more balanced operation of the equipment.

Self-cleaning screen system

Three types of screen cleaning systems are available to increase screen utilization.