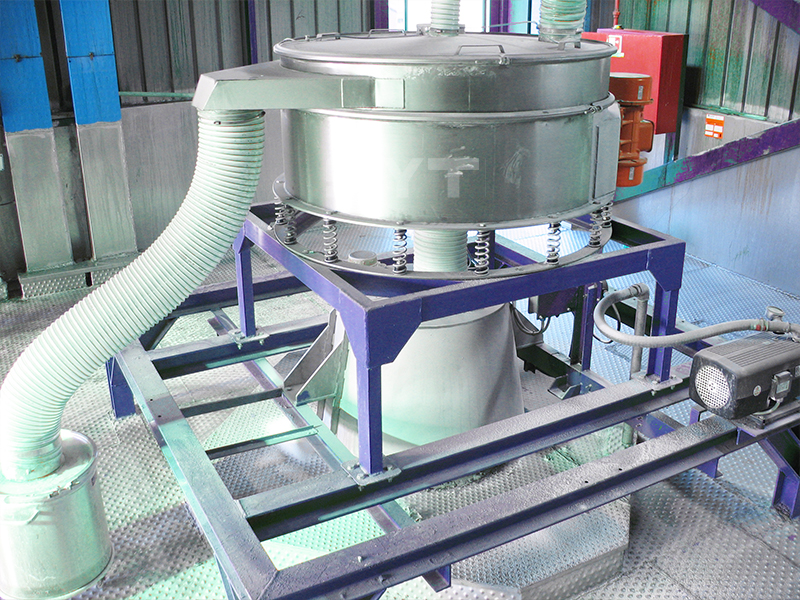

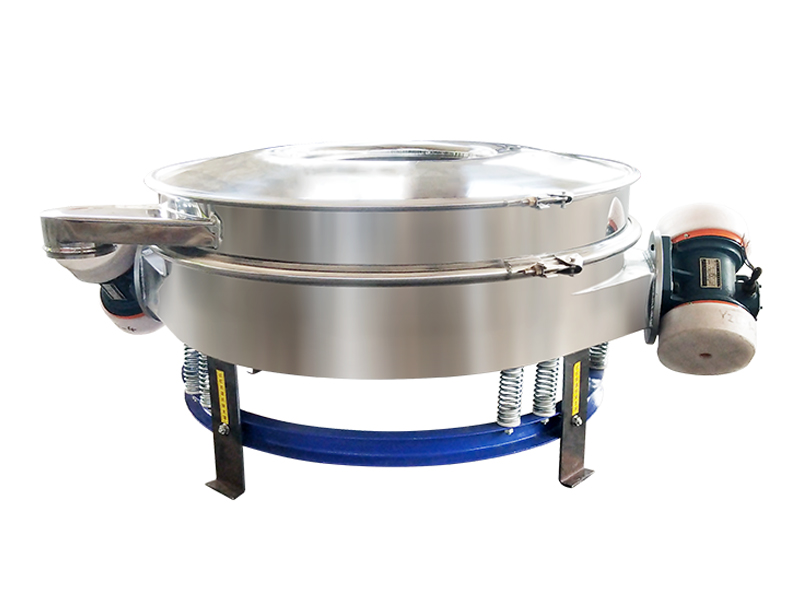

The direct discharge sifter machine is a circular vibrating sieve used specifically for sieving and grading fine powder materials. It is commonly referred to as a flour sieve because of its frequent use in the food industry, particularly for sifting flour to remove impurities and achieve the desired particle size.

- Model: SYM-600/800/1000/1200/1500mm

- Material: Stainless Steel 304/316

- Mesh Size: 2-100 mesh

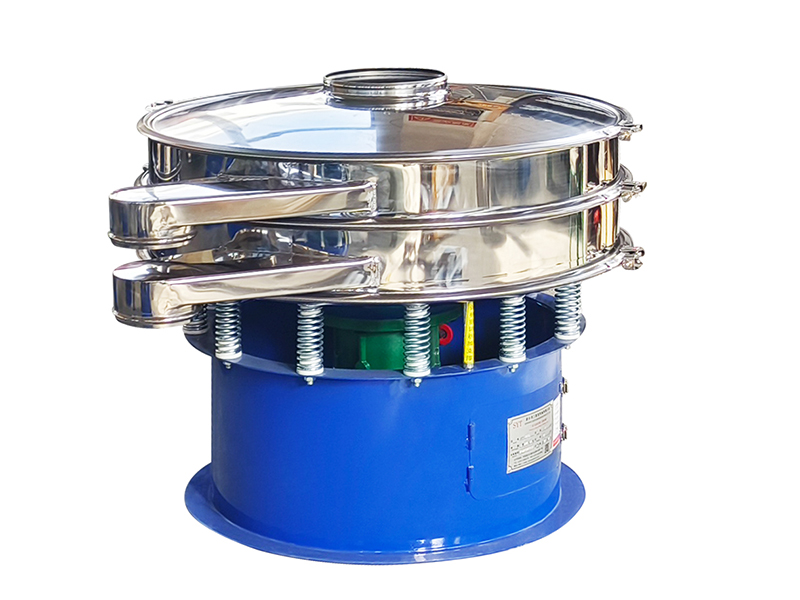

- Layers: 1-2 layers

- Motor: single or double motor

- Capacity: 1-3 tons/hour

- Customized: Acceptable

Price: $790 – $2900 /Set

Working Principle

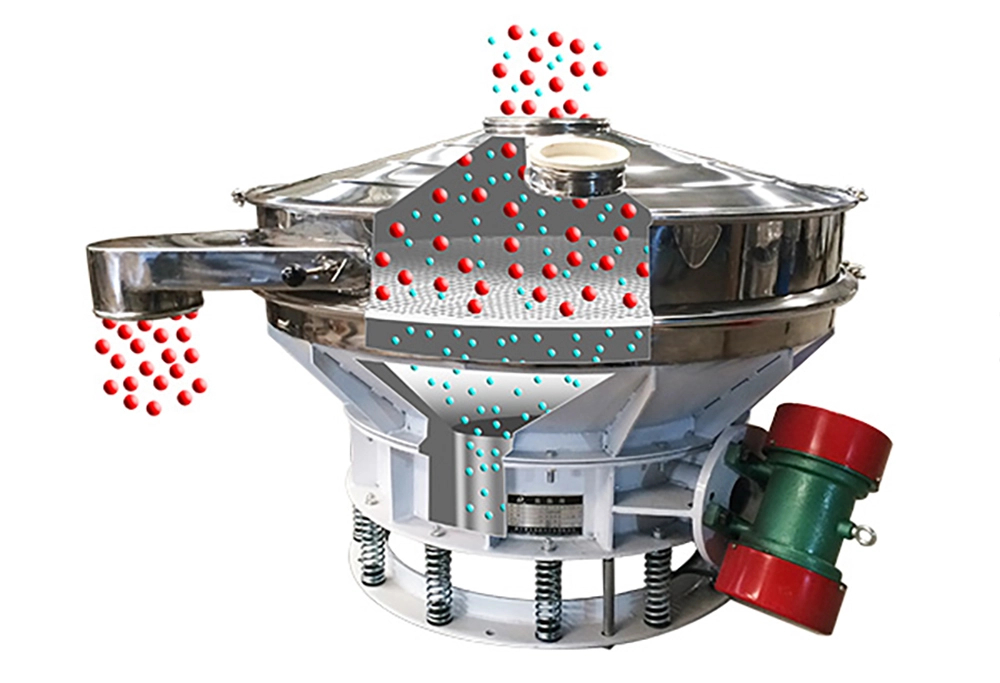

The working principle of the direct discharge sifter machine involves the use of vibration to separate and classify materials. It is designed to efficiently sieve and screen fine powders, granules, and other materials. Here’s how it works:

Material Feed: The material to be sieved or screened is fed into the direct discharge sifter through an inlet or hopper.

Vibration Generation: The direct discharge sifter is equipped with one or two vertically mounted motors, depending on whether it’s a single-motor or double-motor sifter. These motors produce vibrations that are transmitted to the sieve deck or screen mesh.

Sieving Surface: The sieve deck or screen mesh is the surface on which the material is placed for screening. The vibrations from the motors cause the sieve deck to vibrate in a vertical or circular motion.

Vortex Motion: The combination of vertical and circular motion generated by the vibrating motors induces a vortex motion of the material on the sieve surface. This motion helps to evenly distribute and disperse the material across the screen, ensuring efficient screening.

Particle Separation: As the material is agitated by the vortex motion on the sieve deck, finer particles pass through the openings of the screen mesh (undersize) and are collected as the screened product. Larger particles that do not pass through the mesh are retained on the sieve surface (oversize).

Discharge: In the case of a double-motor direct discharge sifter, the automatic discharge function comes into play. The vortex motion and agitation of the material allow for continuous and smooth discharge of the screened material from the sieve. The material flows out from the bottom discharge port without the need for manual intervention.

Single-Motor Direct Discharge Sifter

In contrast, the single-motor direct discharge sifter machine is equipped with a single motor, providing only one vibration source.

The material primarily moves up and down on the screen’s surface due to the single vibration source. The movement is relatively simpler than the double-motor sifter’s vortex motion. Unlike the double-motor sifter, the single-motor direct discharge sifter has no automatic discharge function. The material may need manual assistance or a separate mechanism to be discharged from the sieve.

This sifter is suitable for applications where moderate throughput is sufficient, and manual discharge of screened materials is acceptable.

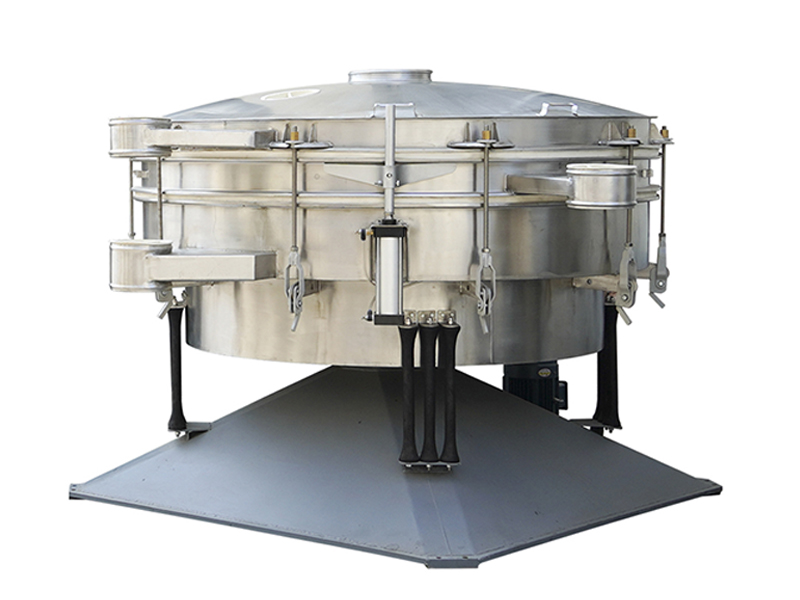

Double-Motor Direct Discharge Sifter

This type of direct discharge screen is equipped with two motors providing dual vibration sources.

The presence of two motors creates a vortex motion in the material on the surface of the screen. Due to the combined effect of the dual vibrations, the material moves in a circular pattern. Dual motor design can automatically discharge materials directly from the sieve. The vortex motion helps promote a smooth, continuous flow of material out of the screen.

This screen is suitable for applications requiring high throughput and automatic discharge of screened material.

Both types of direct discharge sifters are used for sieving and screening fine powders, and they share common features such as the bottom discharge port. However, the presence of one or two motors and the resulting motion pattern differentiate their capabilities, especially in terms of discharge function and capacity. The choice between the two types depends on the specific requirements of the application, including the desired throughput, level of automation, and discharge process.

Features

- The structure is simple and compact, small in size, does not take up space, and is easy to move.

- All stainless steel design, beautiful appearance, and durability.

- Low working noise, ultra-low silent design; low energy consumption, and high efficiency.

- Automated operation, capable of 24-hour continuous production;

- Fully enclosed structure to prevent flying dust and is environmentally friendly.

- The large-flow discharge port is at the bottom, which facilitates the installation of equipment for assembly line operations.

- The upper discharge port can be adjusted arbitrarily within 360°, which is convenient for installation and use.

- With the new mesh frame structure, the mesh has high tension and long service life, and customers can quickly replace the screen themselves.

Screen Support

Screen Support Feeding Port

Feeding Port Motor

Motor Valve

Valve

Specifications

| Model | Power(kW) | RMP(r/min) | Sieve Diameter(mm) |

|---|---|---|---|

| SYTD-600 | 0.18 | 1460(960) | 520 |

| SYTD-800 | 0.25 | 720 | |

| SYTD-1000 | 0.37 | 890 | |

| SYTD-1200 | 0.55 | 1090 | |

| SYTD-1500 | 0.75 | 1390 |

Application

The flour sifting machine is a coarse screening equipment among fine screening equipment. It can filter powders and granules within 200 meshes. They have a large processing capacity and are easy to integrate into production lines. It is widely used in washing powder, chemical fertilizers, medicinal powders, salt, monosodium glutamate, seasonings, milk powder, starch, flour, and rice noodles, carbon powder, graphite powder, etc.