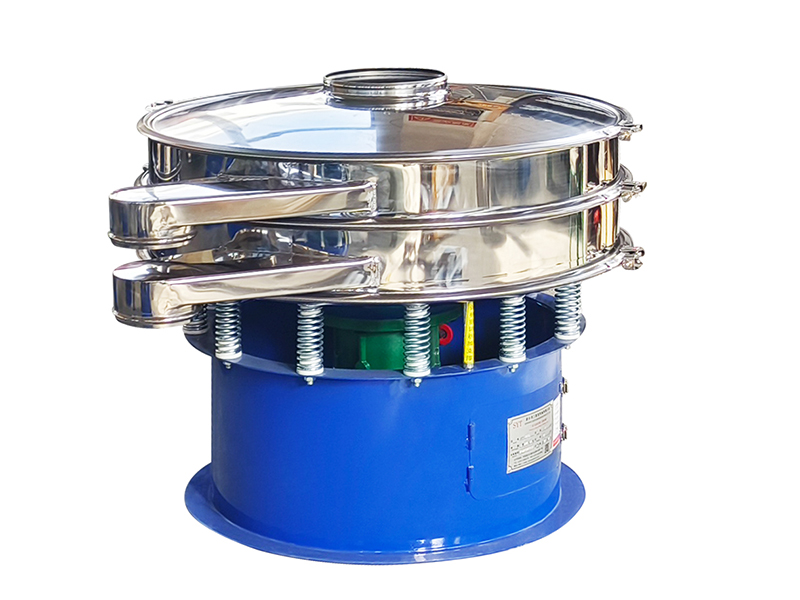

Frac Sand Gyratory Screen

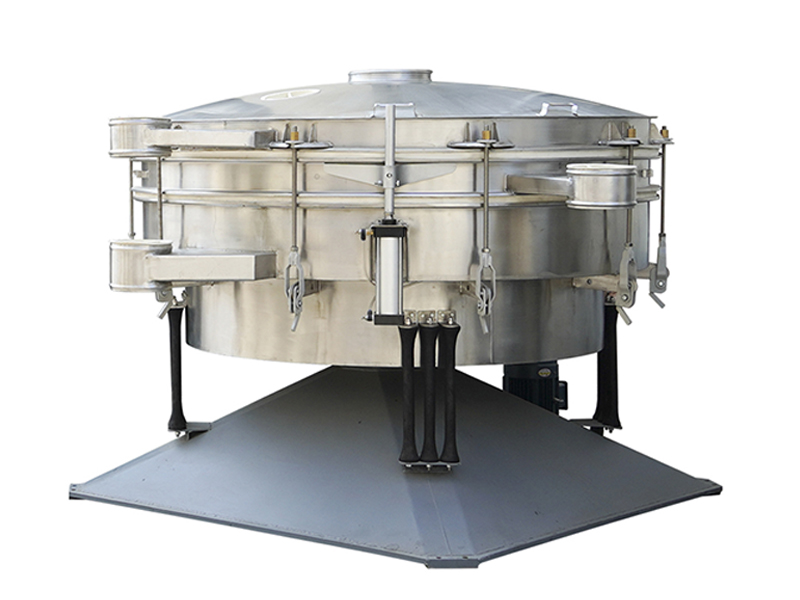

Frac sand gyratory screen, also known as a gyratory sifter or gyratory separator, is a specialized vibrating screen used in various industrial applications to separate materials based on particle size. They are particularly useful for sifting and classifying bulk materials, ensuring the quality and consistency of the end product, and removing impurities or oversized particles.

- Model: FYBS-1536 , FYB-S2040

- Material: Carbon Steel

- Mesh Size: 2-300 mesh

- Layers: 1-10 layers

- Motor Power: 5.5kW/7.5 kW

- Capacity: 100kg – 15 Tons/hour

- Customized: Acceptable

Price: $14800.0 – 23400.0 / Set

Application

- Abrasive material and ceramic industry: building sand, mica, alumina, abrasive, refractory material, slurry, etc.

- Chemical industry: resin pigment, medicine, grease, paint, palette, etc.

- Food industry: sugar, salt, alkali, gourmet powder, starch, milk powder, yeast powder, pollen, food additives, etc.

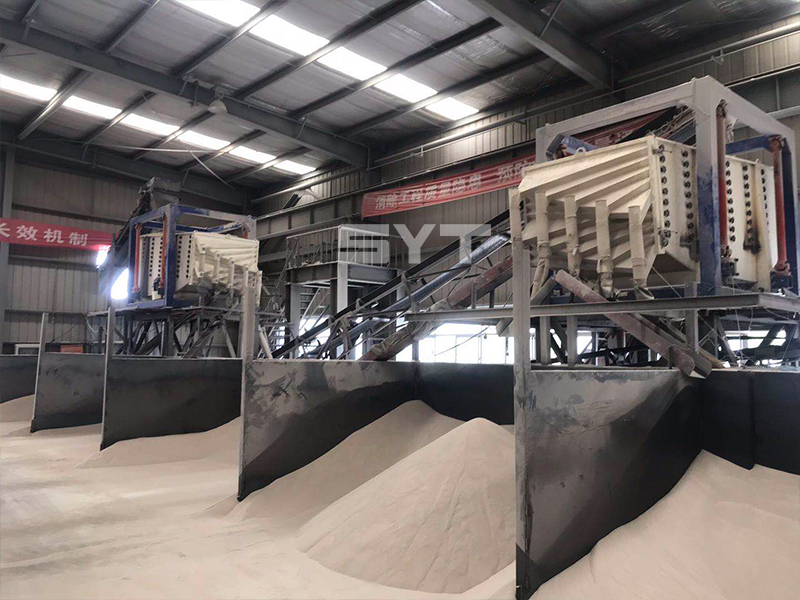

- Metallurgy and mining industry: quartz sand, ore, meteorite, garnet, etc.

- Mechanical industry: casting sand, powder metallurgy, electromagnetic material, and metal powder, etc.

Ceramic sand

Ceramic sand Perlite

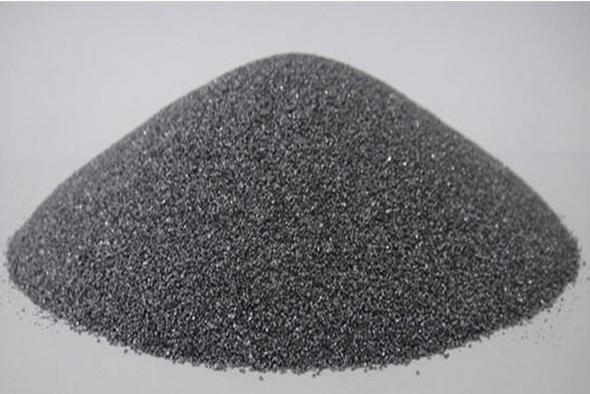

Perlite Emery

Emery Metal silicon powder

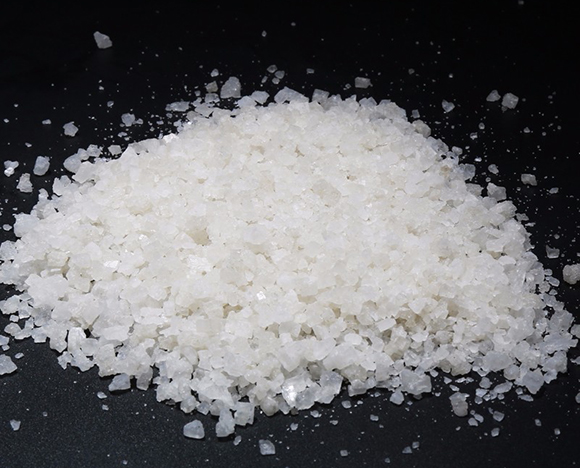

Metal silicon powder Industry salt

Industry salt Cork powder

Cork powder Calcium Carbonate

Calcium Carbonate Plastic particles

Plastic particles Spices

Spices

Working Principle

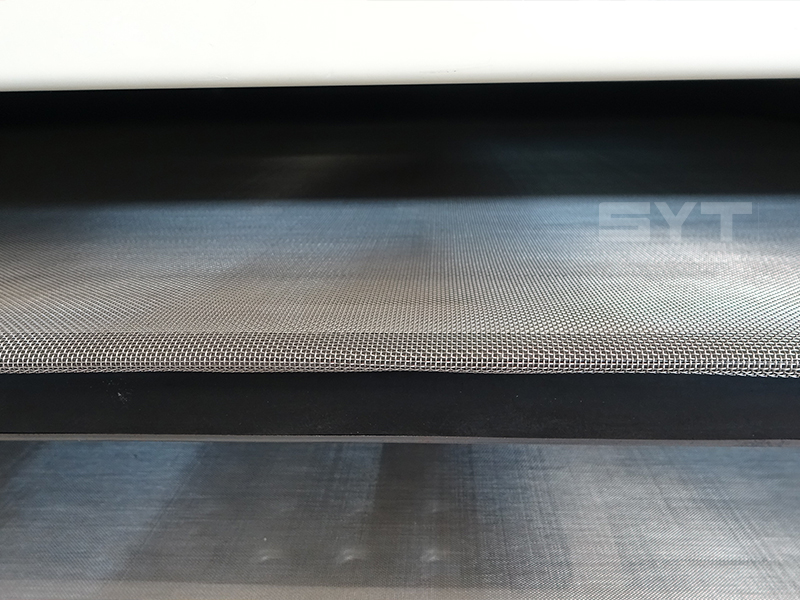

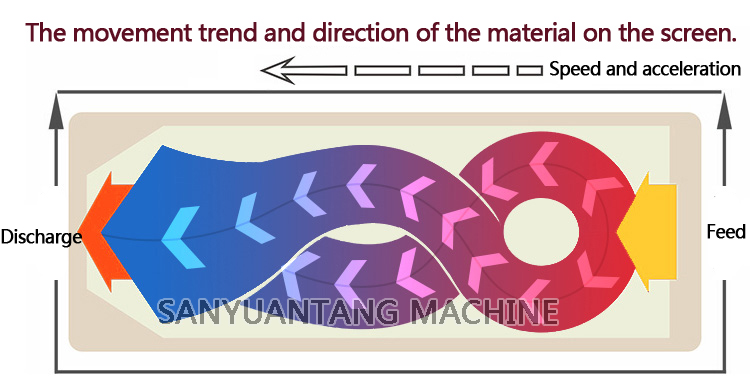

After the Gyratory screen is started, the shaking body of the screen machine, that is, the screen box, reciprocates back and forth under the action of inertial force. The screen box drives the screen surface to shake periodically so that the materials on the screen surface make directional jumping movements together with the screen box.

During this period, materials smaller than the screen pore size fall to the lower layer through the sieve holes and become under-screen materials. Materials larger than the screen pore size are discharged from the discharge port after continuous rolling and jumping motion, thereby completing the screening work.

Specifications

| Model | Screen size | Screening area | Screen inclination | Layers | Power | Number of turns | Case travel |

|---|---|---|---|---|---|---|---|

| FYBS1536 | 1.5*3.5 m | 4.5-9 m2 | 5-8 | 1-10 | 5.5 | 180-260 | 25-60 mm |

| FYBS2040 | 2.0*4.0 m | 8-9 m2 | 5-8 | 1-10 | 7.5 | 180-260 | 25-60 mm |

Videos

Features

Up to 5 times the output per unit area; accurate to 6 levels of separation, and the screening efficiency is as high as 90%-99%.

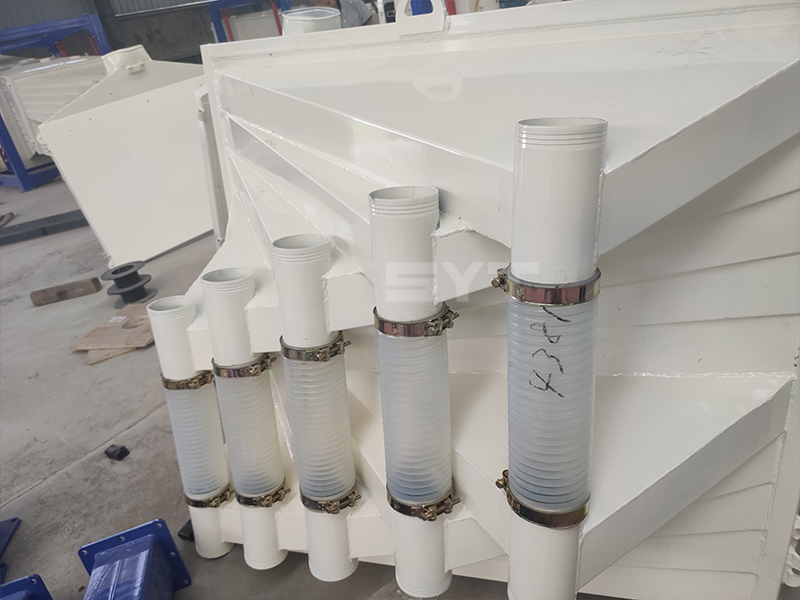

Each layer of screen mesh is equipped with a screen mesh anti-clogging cleaning device. The screening machine continuously cleans the mesh mesh under working conditions, and the mesh mesh has almost no clogging.

New technology

The large-scale electrostatic spraying process makes the equipment more beautiful, wear-resistant, and rust-proof.

Longer life

For flexible screening, the acceleration is 4-5 times lower than that of ordinary vibrating screens, and the service life is increased, thereby reducing maintenance costs.

Easy to operate

Network replacement is more convenient, simple to operate, and runs smoothly.

Environmental friendly

Fully enclosed structure, dust does not fly, and the screen machine has small vibration and low noise (less than 75 decibels), which meets environmental protection requirements.

Customer Site

Why Choose US?

Recommended Products

Get a Quotation

Custom Gyratory Screen

Please tell us your specific requirements and we will customize the best product solution for you