Lime Powder Sieve Machine

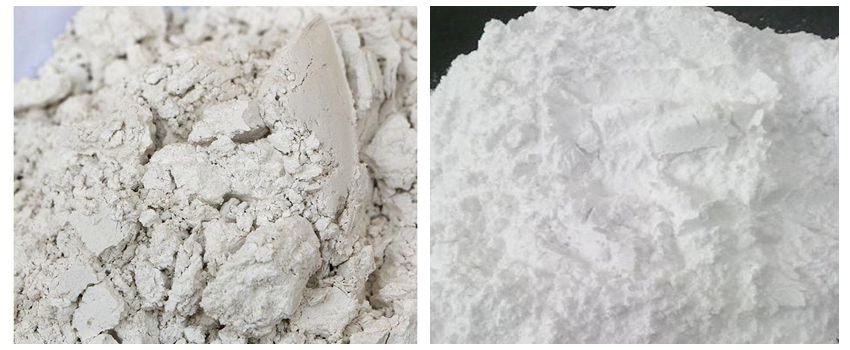

The lime powder sieve machine is mainly used for impurity removal and screening applications of limestone and lime powder. It sieves lime powder into grades of different particle sizes. Lime powder, also known as hydrated lime or calcium hydroxide, is a fine, white powder obtained by mixing water with quicklime (calcium oxide).

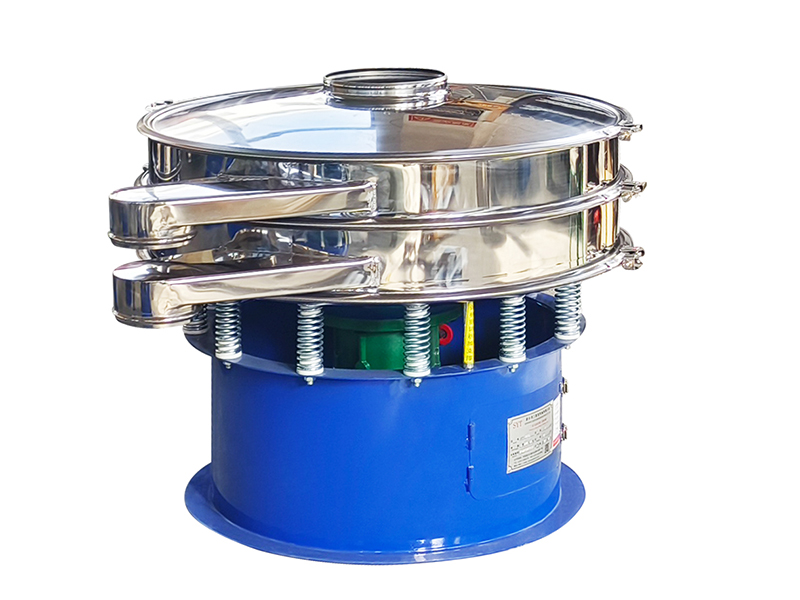

The lime powder sieve machine uses a vibration motor as the vibration source to throw the materials on the screen. At the same time, it moves forward in a straight line, and the material enters the feed port of the vibrating screen evenly from the feeder and passes through the multi-layer screen to produce several specifications of upper and lower objects, which are discharged from their respective outlets respectively, thereby achieving screening purposes.

Lime Powder Sieve Machine Functions:

Removing impurities: Sieving can help remove any large particles, debris, or impurities from the lime powder, ensuring that the final product is clean and free of contaminants.

Breaking up lumps: Lime powder can sometimes form lumps during storage or transportation. Sieving helps to break up these lumps, resulting in a finer and more consistent texture.

Ensuring uniformity: Sieving helps to achieve a consistent particle size in the lime powder, which is important for applications where uniformity is required, such as in construction, agriculture, or manufacturing processes.

Why choose Lime Powder Sieve Machine

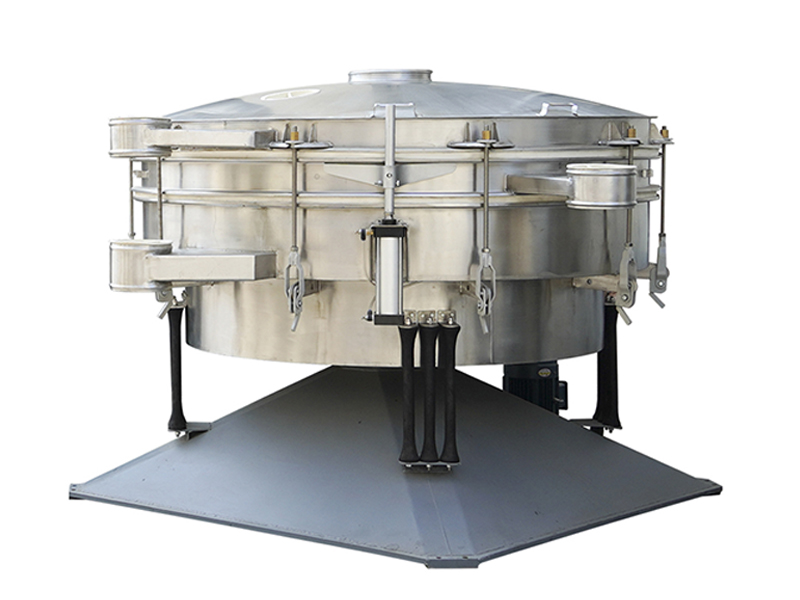

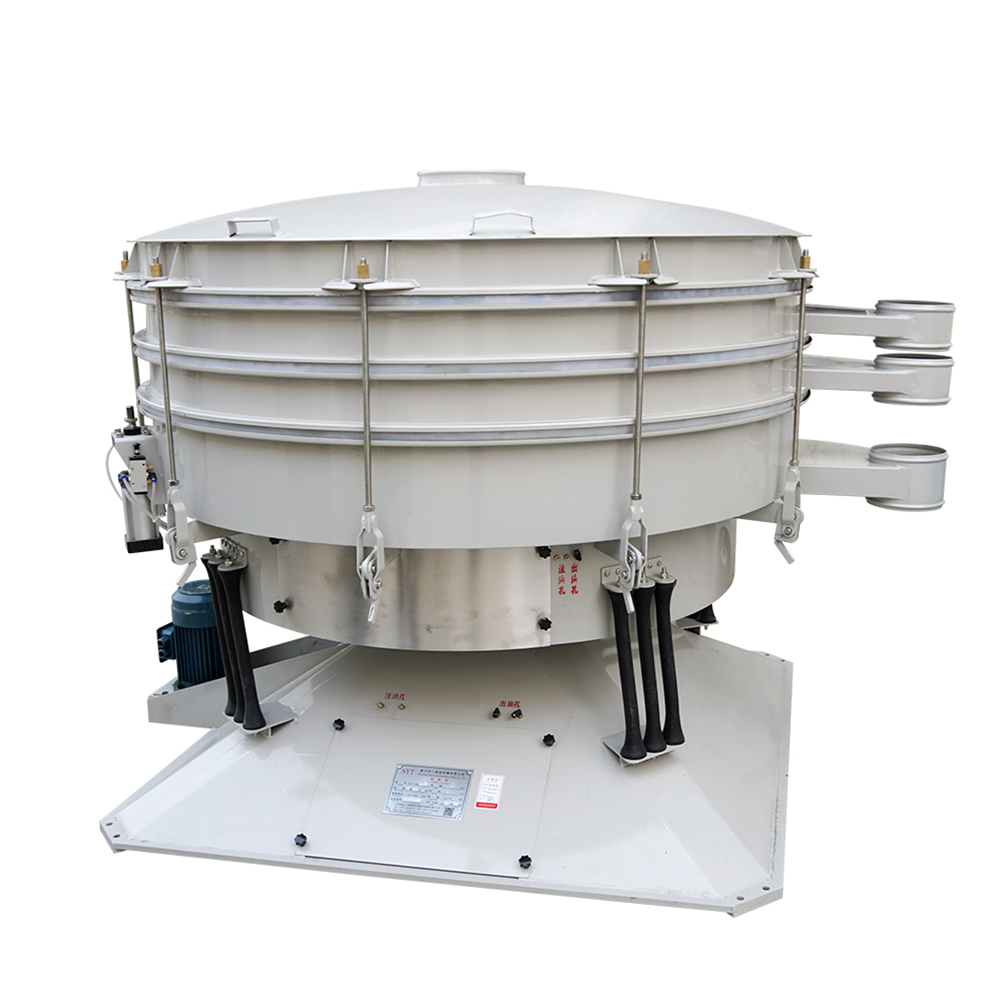

When selecting a lime powder sieving machine, taking into account factors such as the product characteristics of lime powder, production capacity, mesh size, cleaning system and type of vibration motion, the tumbler screen is the most suitable screening equipment.

The lime powder sifter machine is a relatively new product in the vibration equipment industry. Its price is generally higher than ordinary rotary vibrating screens and linear vibrating screens, but why is it still popular among lime powder merchants?

Tumbler Screen Working Principle

Rotary motion: The tumbler screen plate of the drum screening machine rotates through a motor with an eccentric hammer. It causes the lime powder to move in a tumbling manner, similar to the motion of a roller or drum.

Screening and separation: When lime powder tumbles on the sieve plate, it is acted upon by a variety of forces, including gravity, centrifugal force, and friction. The lime powder is layered and separated into different sizes based on size and shape.

Discharge: The separated lime powder is discharged through different outlets or nozzles to collect the required coarse powder and fine powder.

Tumbler screening machines can efficiently handle a variety of materials including fine powders, granules, and bulk solids. Its unique rotational motion and gentle screening action make it suitable for applications where delicate or fragile materials need to be separated without damaging the particles.

Tumbler Screen Machine Features

1.Screening Efficiency

After comparison, it is found that: for coarse materials above 30 mesh, the output of industrial vibrating screen and swinging screen is basically the same, but the maintenance cost of swinging screen is relatively low; for materials of 30-500 mesh, the output of swinging screen is much higher than that of vibrating screen, swinging screen The sieve is 5-10 times that of the vibrating sieve; in addition, for hard materials with severe screen wear, the service life of the oscillating sieve can be doubled.

- Screening Area

Take the more mature circular vibrating screen in the market as an example, its screening area is generally below 1500mm, and the maintenance rate of models above 1500mm is very high. This is mainly because the vibrating motor used in the 1500mm circular vibrating screen has a large power, which will damage the body while screening materials, and the larger the frame, the more serious the damage. If it is multi-layer screening, the effect will be better. Difference.

The swinging screen uses an ordinary motor. After the speed is changed, the entire frame body performs a low-speed rocking motion, and the body does not vibrate, so the frame body is basically not damaged. At present, the model range of the swinging screen has reached 600mm-2600mm. From this point of view, the model and output range of the vibrating screen are relatively large, which can fully meet the requirements of customers with large output and high precision beyond prehistoric times.

- Maintenance Rate and Service Life

The powder screening machine uses the principle of high-speed vibration. The vibration is very destructive to the machine itself, and it is prone to vibration cracking or deformation after a long time. Therefore, the breakage of the screen is often not caused by normal wear, but by its own friction. In addition, the noise of the vibrating screen is relatively large, the service life of the vibrating mo - tor is short, and the maintenance rate is high.

- The swinging screen adopts the low-speed swinging principle, which ensures the service life of the equipment, reduces the maintenance cost, reduces the noise of the equipment, and makes the use of the equipment safer.

- Impact on Materials

As we all know, the vibrating screen uses the principle of high-speed vibration to sieve materials. It is precisely because of the high-speed vibration that the shape of the material will be destroyed, so many granular crystalline crispy materials are not suitable for vibrating sieve screening, such as chicken essence, monosodium glutamate, sugar, Deli and more. The oscillating screen is a slight elliptical rocking motion, without high-speed vibration, which has little impact on the material, does not damage the shape of the material, and greatly improves the yield of the material. - Price and Affordability

On the surface, vibrating screens and their accessories are relatively cheap. This is because there are many manufacturers of rotary vibrating screens and the competition is fierce, so that the price of vibrating screens is infinitely close to the cost, and the price is very low. As a new product with relatively high technical content, the swing sieving machine is more complicated than the rotary vibrating screen, so the current price is still relatively high. - However, considering the output, maintenance rate, service life and other factors of the two products, in the long run, the swinging screen is more affordable and superior than the vibrating screen, and can achieve both output and precision.