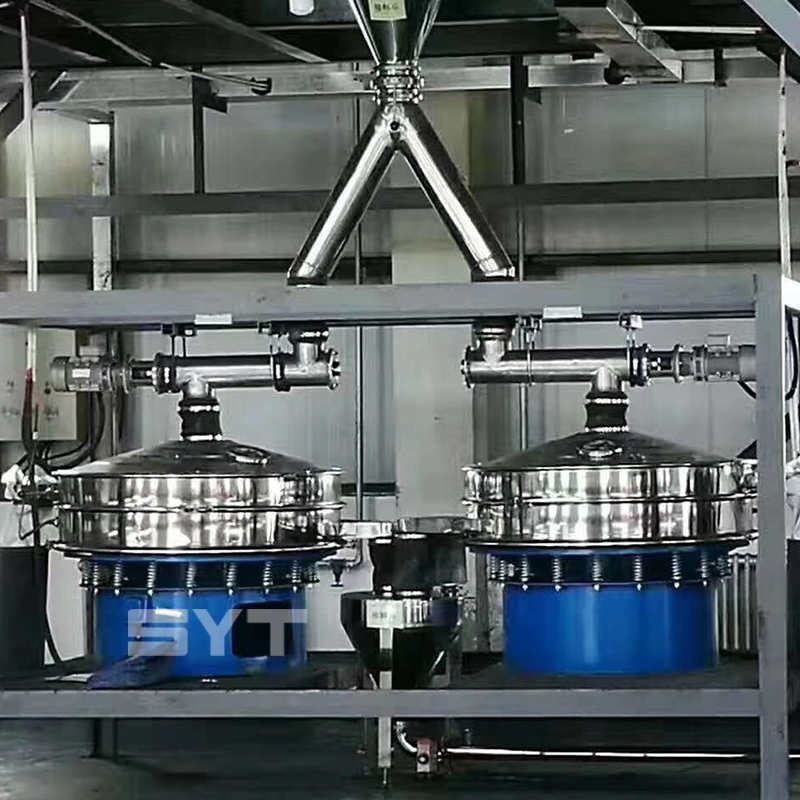

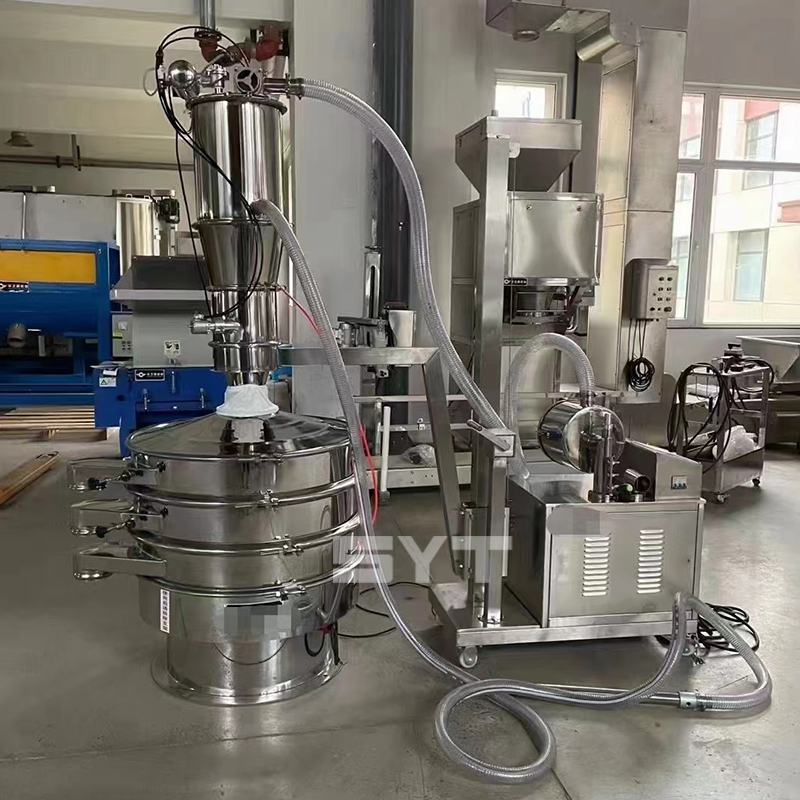

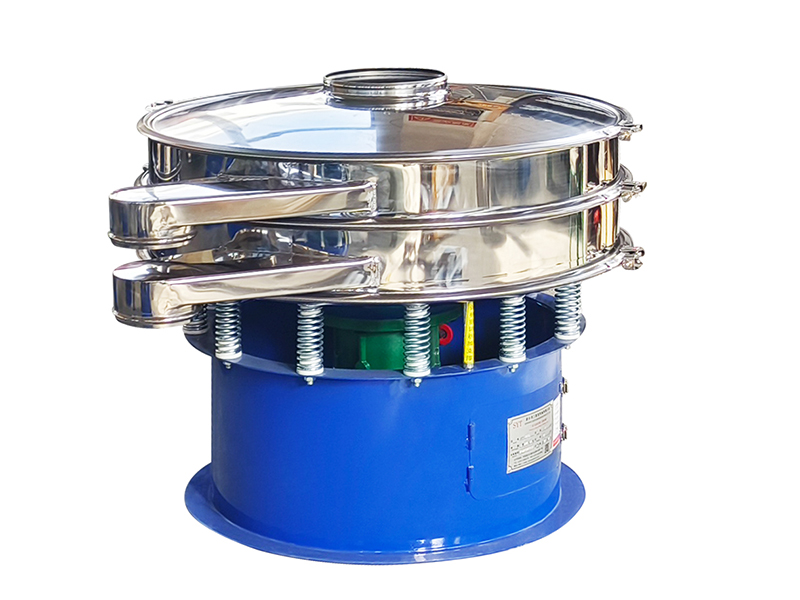

The rotary vibrating screen is a kind of round screening machine, applicable to the filtration, debris removal, and classification of various materials, such as powder, granules, liquid, and so on. Rotary vibration sieve has a simple structure, convenient operation, easy maintenance, small volume, high screening efficiency, widely used in chemical, food, medicine, metallurgy, ceramics, paper making, electronics, and other industries.

- Model: SY-600/800/1000/1200/1500/1800 mm

- Material: Stainless Steel 304/316/Carbon Steel

- Mesh Size: 5-500 mesh

- Layers: 1-5 layers

- Motor Power: 0.25-3 kw

- Capacity: 100Kg – 3 Tons/hour

- Customized: Acceptable

Price: $799 – $3999 /Set

Application

- Chemical industry

- Resin, coating, industrial drug, cosmetics, paint, and so on

- Food industry

- Sugar powder, starch, salt, rice flour, milk powder,soya-bean milk, egg powder, soy sauce, fruit juice.

- Metal metallurgy mining

- Aluminum powder, lead powder, copper powder, ore, alloyed powder, kaolin, lime, quartz sand, etc.

- Pollution treatment

- Waste oil, waste water, dyeing wastewater, auxiliaries, activated carbon, etc.

Flour

Flour Milk Powder

Milk Powder Oil Fracturing Proppant

Oil Fracturing Proppant Grain Pellets

Grain Pellets Medicine Powder

Medicine Powder PP/PE Granules

PP/PE Granules Paint

Paint Metal Powder

Metal Powder Emery

Emery

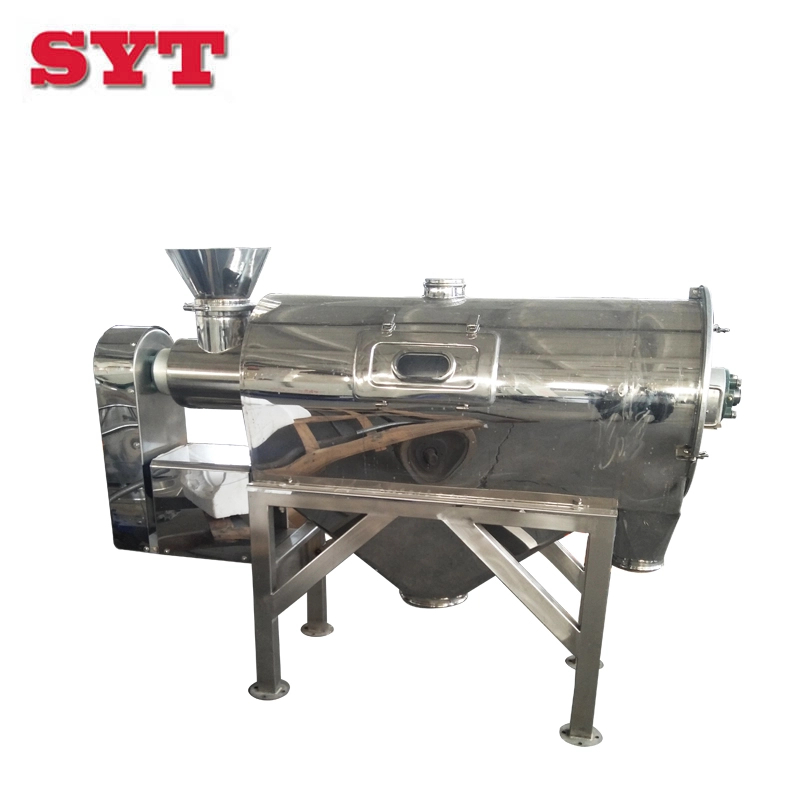

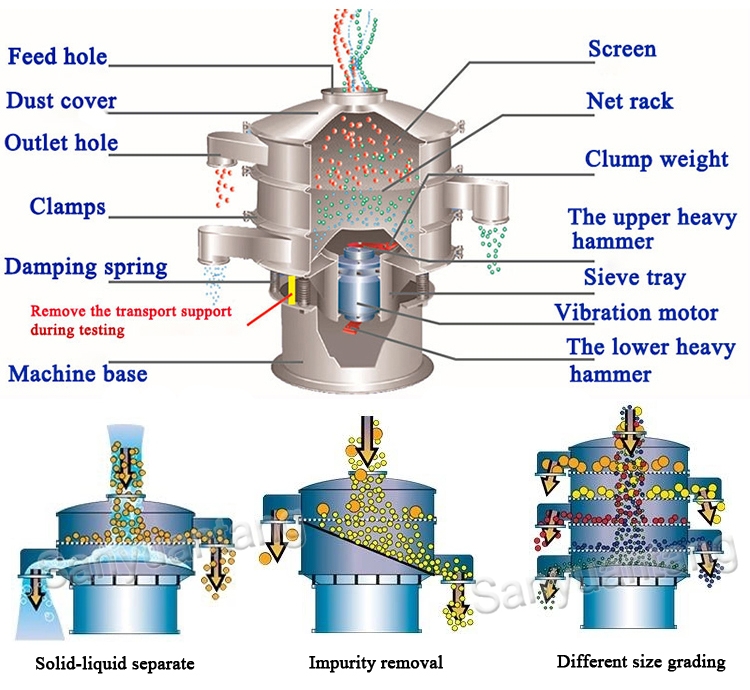

Working Principle

The rotary vibrating sieve is a motor for a vertical excitation source, the motor and lower eccentric weight are installed at both ends of the motor rotary motion into a horizontal, vertical, inclined three elementary motions, and then the movement passes to the screen surface. Adjust the upper and lower ends of the phase angle, the material can change the trajectory of the screen surface.

The powder rotary vibrating sieve machine is fit for dry and wet sieving, classification of powdery, granular, and filamentary materials, and dehydration of materials. If fine sieving is required it can be satisfied by adopting a high-efficiency screen mesh-cleaning device to improve the sieving. For wet sieving, it is especially fit for the separation of sludge (wastewater) and preliminary compression of mixed matter of solid and liquid materials.

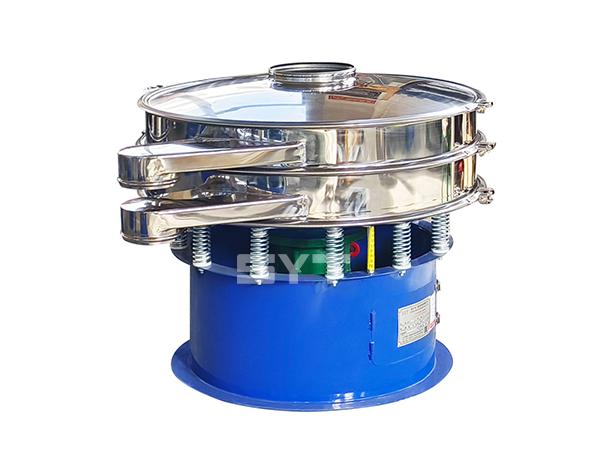

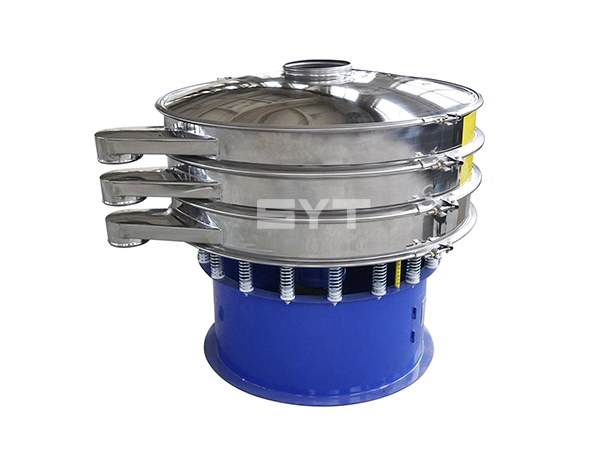

Structures

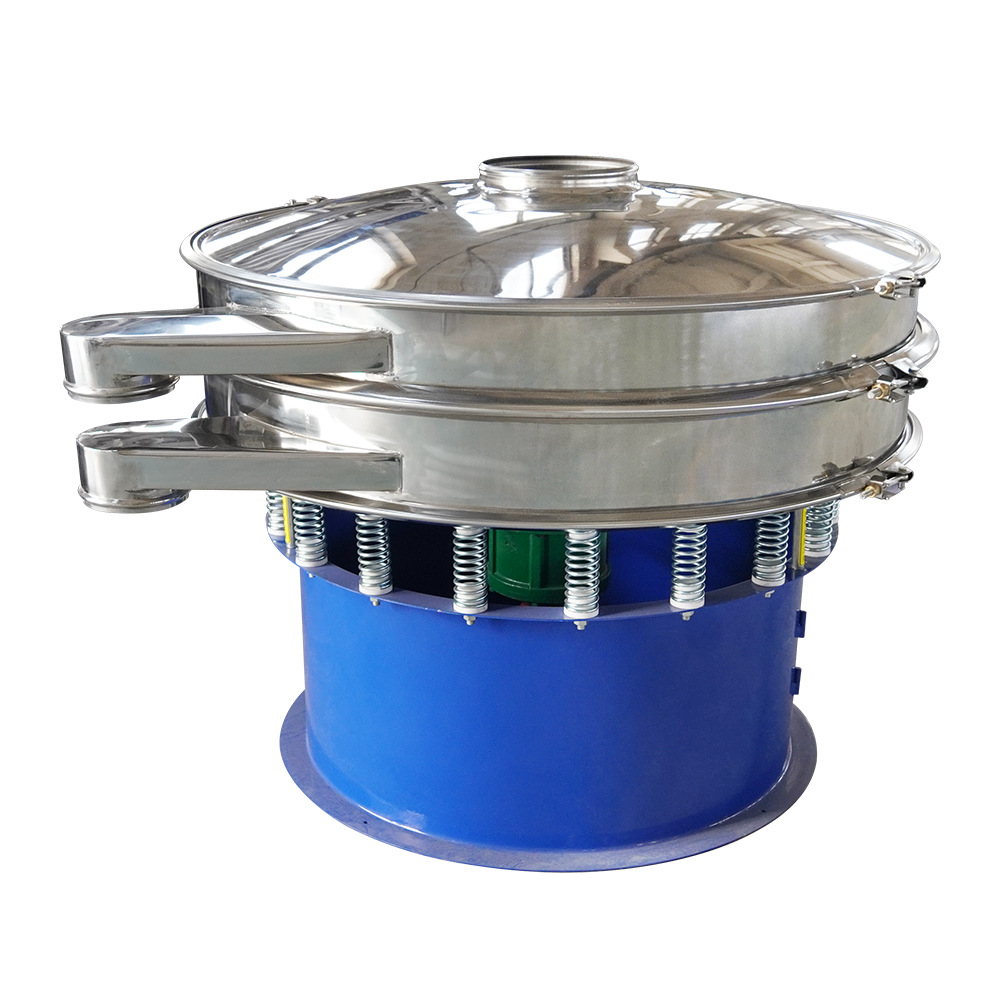

The rotary vibrating screen comprises a dust cover, screen frame, screen mesh, mesh frame, mesh clearing device, motor (vibration source), shock absorbing spring, base, and other parts.

- Dust cover: Composed of an inlet and inclined cone, the lower end is connected to the screen frame to prevent the workshop dust from falling into the material when the vibrating screen is working. Commonly used materials are stainless steel, carbon steel, and plastic. And so on 3 kinds of materials.

- Screen frame: Made of steel plate rolled and welded, with bearings at the upper and lower ends, and a flange inside the lower part to fix the net components’ structure.

- Vibrating motor: Vertical vibrating motor, divided into 2, 4, 6, 8, horizontal four specifications, vibration times were 2870, 1460, 980, 740RPM, can be designed for explosion-proof type (flammable and explosive occasions).

- Mesh: 600mm, 800mm, 1000mm, 1200mm, 1500mm, 1800mm, etc., made of stainless steel, carbon steel, plastic.

- Mesh cleaning device: It can clean the clogged materials in the screen mesh to improve the output. It is made of silicone and rubber. Ultrasonic cleaning device (635 mesh fine powder with static electricity) is also available.

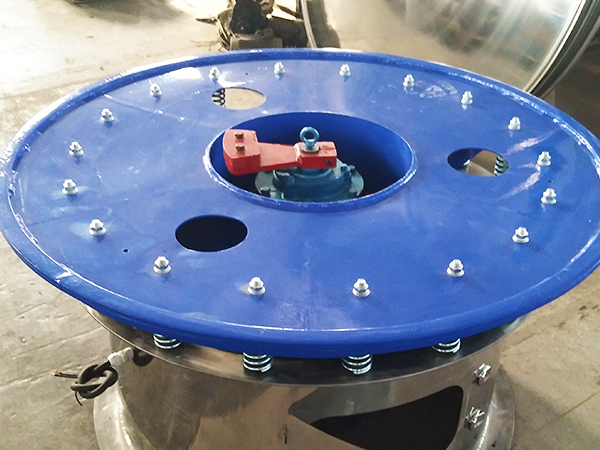

- Damping spring: There are 12-20 vibration isolation springs along the vibration transmission body, and the base is made of welded steel coils. There is an access door and electrical switch seat on the bottom wall, and a ring flange welded on the upper part of the base wall, which is connected with the vibration-transmitting body through the vibration isolation spring.

Gallery

Feeding Hole

Feeding Hole Outlet Hole

Outlet Hole Screen

Screen Gate

Gate Damping Spring

Damping Spring Vibration Motor

Vibration Motor

Specifications

| Model | Layer (s) | Granularity (mm) | Sieve Mesh | Effective Diameter (mm) | Power (KW) | Capacity(Kg/h) |

|---|---|---|---|---|---|---|

| SY-XZS400 | 1-3 | <20 | 2-500 mesh | 380 | 0.25 | 100 |

| SY-XZS600 | 1-3 | <20 | 3-500 mesh | 580 | 0.55 | 200 |

| SY-XZS800 | 1-5 | <30 | 3-500 mesh | 780 | 0.75 | 500 |

| SY-XZS1000 | 1-5 | <30 | 3-500 mesh | 970 | 1.1 | 800 |

| SY-XZS1200 | 1-5 | <30 | 3-500 mesh | 1170 | 1.5 | 1200 |

| SY-XZS1500 | 1-5 | <50 | 3-500 mesh | 1470 | 2.2 | 1500 |

| SY-XZS1800 | 1-5 | <50 | 3-500 mesh | 1770 | 3.0 | 2000 |

Custom according to Your Needs

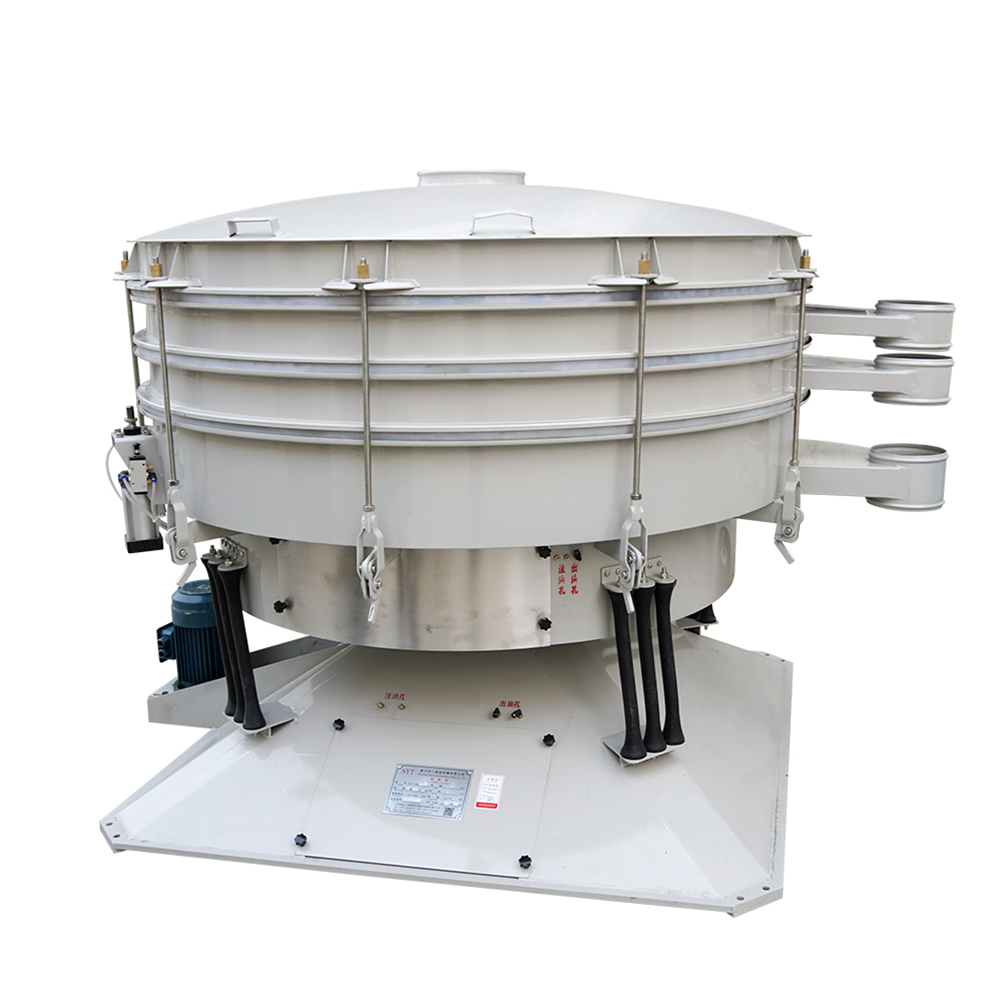

The standard rotary vibrating screen body and material contact part for the selection of 304 stainless steel material, part of the machine base is made of ordinary carbon steel material, according to the user’s requirements of the whole machine made of stainless steel material (stainless steel vibrating screen) and plastic vibrating screen designed for special materials, etc., and also according to the specific needs of screening materials to choose the number of screen mesh layers.

To meet the material screening requirements of special industries, we can also customize the design of inline type (general type), gate type, add edge type vibrating screen, and so on.

Contact Part Stainless Steel + Carbon Steel

Full Stainless Steel

Carbon Steel

Anti Corrosion Plastic PP

Videos

Features

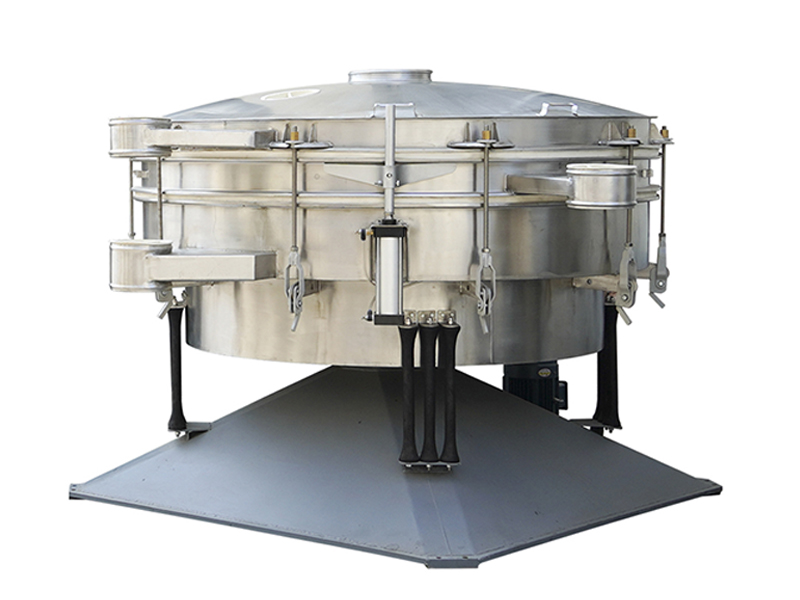

Small size, lightweight, and easy to move. The direction of the discharge port can be adjusted at will, and thick and fine materials are automatically discharged and can be operated automatically or manually.

The screening precision is high, the screening is as fine as 600 mesh or 0.02mm, and the filtration is as small as 5 microns. Any powder, granule, or slime can be used.

Classified screening

Classified screening, which can screen one to five layers of mesh, and can perform two to six levels of sorting or filtration at the same time.

screen not easily clogged

The screen is not easily clogged and the powder does not fly. Equipped with a screen cleaning device, it can reduce the blocking of materials during the screening process.

Easy to change the screen

Special grid design (mother-and-child type). The screen lasts a long time. Easy to change the screen. It only takes 3-5 minutes. Easy to operate and easy to clean.

high power Motor

It adopts a flange motor, which has high power, high screening efficiency, and low noise, there is no mechanical action. Easy to maintain.

Customer Site

FAQS

Why Choose Us?

Recommended Products

Cases

Get a Quotation

Custom Your Vibrating Screen

If you want to buy the rotary vibrating screen, please tell us the specific needs, and we will reply to you ASAP: