The powder sieving machine also called a powder sifter machine or powder screening machine, is a vibrating sieve machine for screening powder and flour in industrial production, commonly used in food processing, pharmaceuticals, and chemicals and cosmetics for quality control and production. The metal powder sifter machine can achieve 6 levels of precision grading and is highly versatile, making it suitable for various materials such as metal powder, food powder, juice powder, drug powder, additives, and other substances.

Powder sieving machines generally choose all stainless steel or carbon steel material, fully closed structure, no dust overflow, low noise, low energy consumption, in line with environmental requirements.

Standard

Full Steel Stainless

Carbon Steel

Ultrasonic vibro sifter

Powder Sieving Machine Features

- Good sealing performance, fully enclosed dust does not fly, high screening efficiency, and high precision.

- Easy to disassemble, easy to clean inside and outside, no hygiene dead corner.

- The discharge port can be adjusted at any 360 degrees, convenient connection with the site.

- The special design of a variety of screen cleaning devices, so that the screen through the net rate is higher, fast discharge, and high yield.

- Low energy consumption, quick start, low noise, no base installation, can be placed in any desired location.

- New mesh frame structure, long service life of the screen, the mesh is not deformed, change the mesh only 3-5 minutes, parts without dead angle, easy to thoroughly clean and disinfect.

- It can be used in single-layer or multi-layer, and it can be screened in multiple levels at one time.

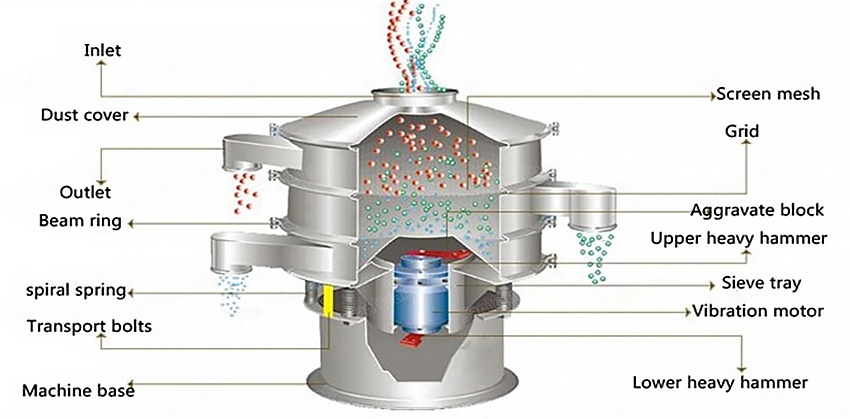

Powder Sieving Machine Working Principle

The metal powder sieving machine utilizes a vertical excitation source, typically a motor, with lower eccentric weights positioned at both ends of the motor to generate a rotary motion. This motion transforms into horizontal, vertical, and inclined movements, which are then transmitted to the screen surface. By adjusting the phase angle at the upper and lower ends of the machine, it is possible to alter the trajectory of the material on the screen surface to separate the particles better, ensuring High efficiency and high precision sieving of the powder.

Powder Sieving Machine Specifications

| Model | Effective diameter(mm) | Layer (s) | Sieve mesh | Power (kw) | Capacity(kg/h) |

|---|---|---|---|---|---|

| SY-XZS400 | 380 | 1-5 | 2-500 mesh | 0.25 | 100 |

| SY-XZS600 | 580 | 1-5 | 3-500 mesh | 0.55 | 200 |

| SY-XZS800 | 780 | 1-5 | 3-500 mesh | 0.75 | 500 |

| SY-XZS1000 | 970 | 1-5 | 3-500 mesh | 1.1 | 800 |

| SY-XZS1200 | 1170 | 1-5 | 3-500 mesh | 1.5 | 1200 |

| SY-XZS1500 | 1470 | 1-5 | 3-500 mesh | 2.2 | 1500 |

| SY-XZS1800 | 1770 | 1-5 | 3-500 mesh | 3 | 2000 |

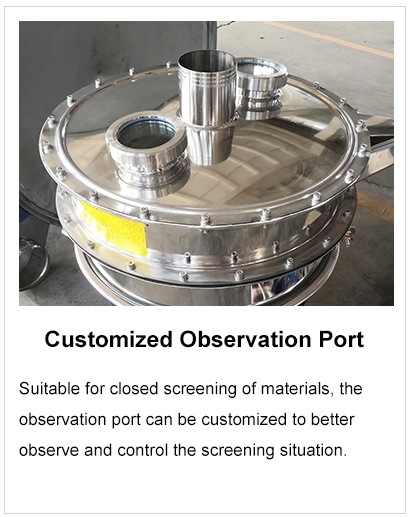

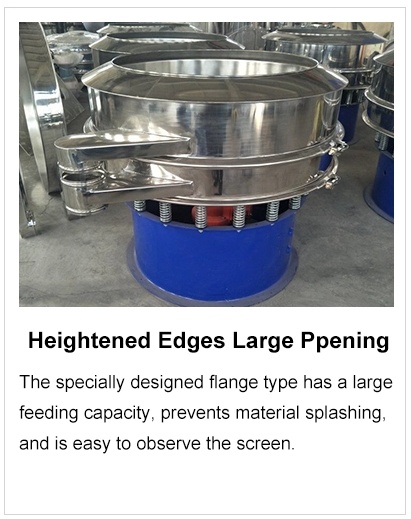

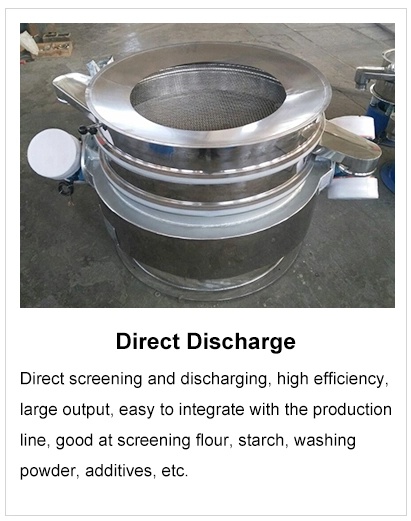

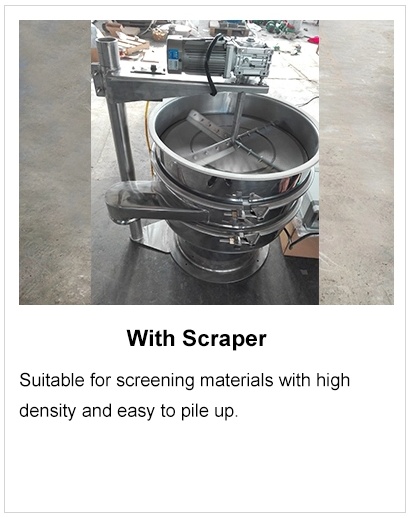

Customization

According to different screening needs, the powder screening machine can be customized with 1-5 layers, and 8 sizes are available: 400mm, 600mm, 800mm, 1000mm, 1200mm, 1500mm, 1800mm, and 2000mm. Its throughput ranges from 100 to 5,000 kg/h, depending on the machine’s product, screen size, and feed flow.

Powder sieving machines can be tailored to meet specific customer requirements, please tell us your needs.

Application

- Metal, metallurgy mining industry: aluminum powder, lead powder, copper powder, alloy powder, welding rod powder, manganese dioxide, electrolytic copper powder, electro-magnetic material, grinding powder, refractory material, kaolin, alumina, quartz sand, etc.

- Pharmaceutical Industry: Chinese medicine, medicine powder

- Chemical industry: resin, paint, cosmetics, paint, medicine, plastic, rubber, etc.

- Food industry: powdered sugar, starch, monosodium glutamate, salt, rice flour, milk powder, egg powder, soy sauce, fruit juice various additives, etc.

- Abrasives, glass, ceramics industry: silica sand, alumina, grinding powder, glass powder, clay slurry, glaze, and so on.

- Others: carbon black, light calcium, additives, pearl powder, etc.

Flour

Flour Milk Powder

Milk Powder Medicine Powder

Medicine Powder Paint

Paint Glass Powder

Glass Powder Metal Powder

Metal Powder Graphite powder

Graphite powder Light calcium powder

Light calcium powder kaolin

kaolin

Different Types of Powder Sieving Machines

For different powder sieving requirements, different sieving machines are used.

Powders can be divided into five grades according to the size of particles: coarse powder, medium powder, fine powder, micro-fine powder, and ultra-fine powder. Particles within the range of 150-500μm are coarse powders, particles with a size of 44-150μm are medium powders, particles with a size of 10-44μm are fine powders, particles with a size of 0.5-10μm are very fine powder and particles with a size of less than 0.5μm are ultrafine powders.

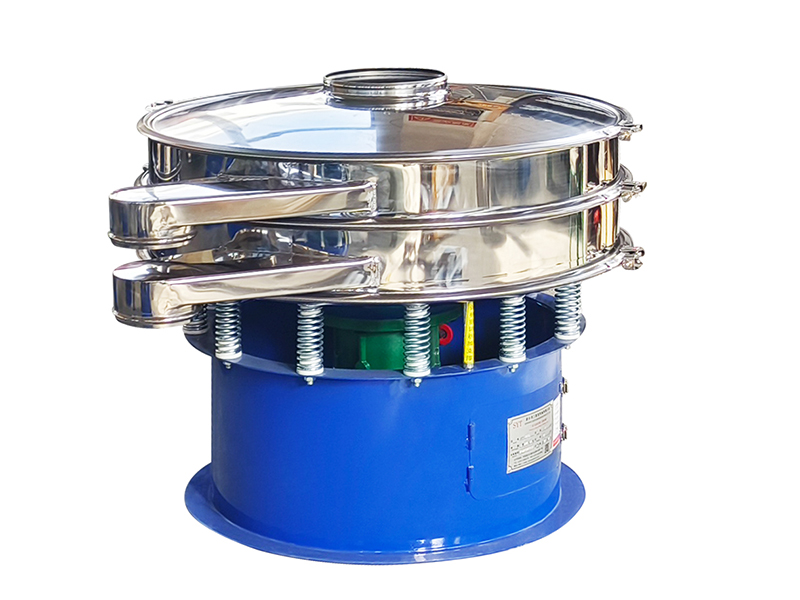

Rotary Vibrating Screen

For coarse powder and medium powder, we can choose rotary vibration sieve equipment to sieve. The rotary vibrating screen is a high-precision coarse and fine particle screening equipment.

It consists of a coarse material outlet, an upper eccentric block, a spring, a lower eccentric block, a motor, a fine material outlet, a screen, etc. The diameter of the screen is generally 0.4 to 0.5 meters, and the number of screens is from one to five layers.

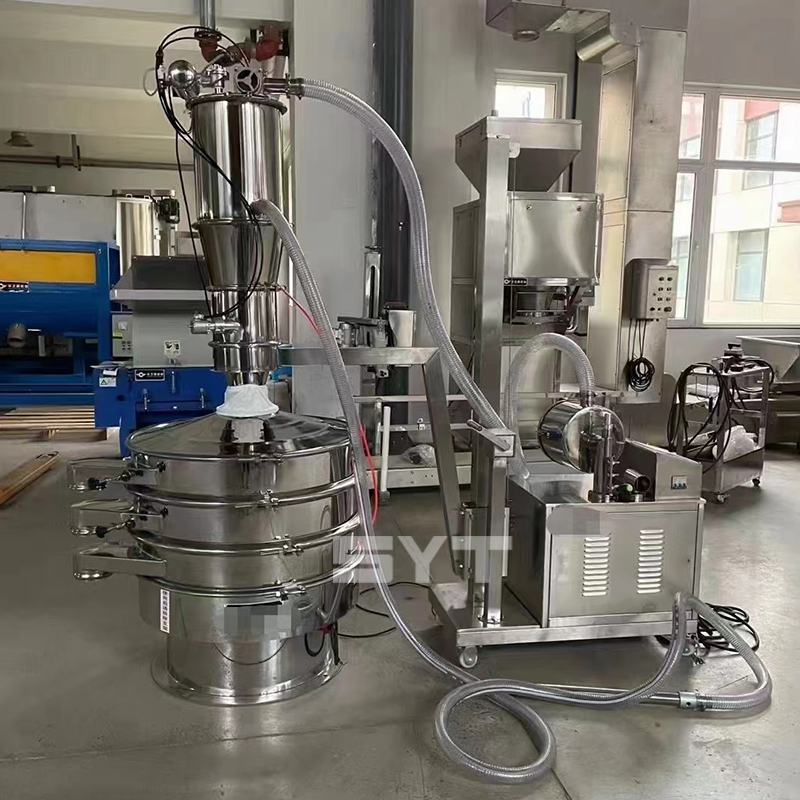

Ultrasonic Vibrating Screen

For finer powder, need to add an ultrasonic screening device, ultrasonic vibrating screen can screen powder as fine as 10μm. 3. for large-scale and large production capacity screening, it is also called three-dimensional vibrating screen.

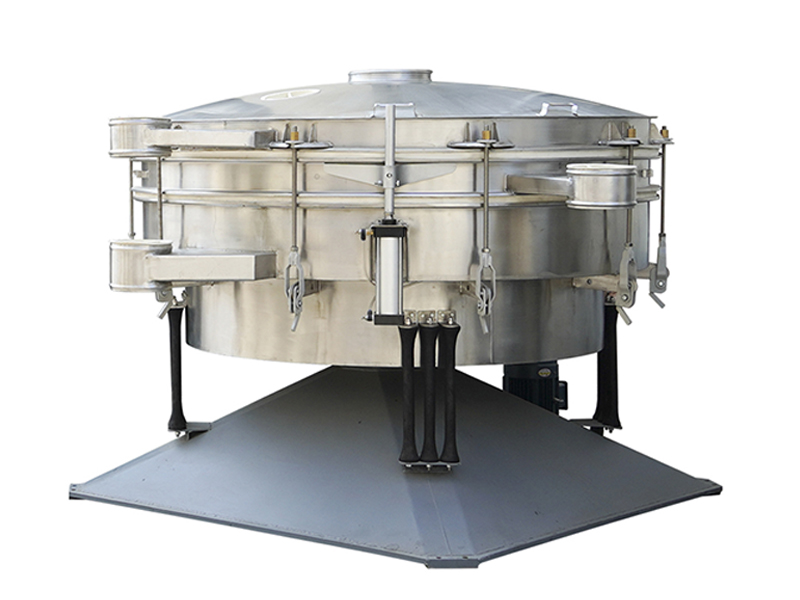

tumbler Screener

For large-scale output screening needs, can choose the tumbler screening machine. Tumbler screen is currently an effective simulation of artificial sieving movement of screening equipment, to meet the large output and high precision screening needs, screening efficiency is 5-10 times the conventional vibrating sieve machine, suitable for powder large handling capacity of industrial requirements.

Powder Sieving Machine Solutions

| Material | Mesh | Capacity | Models |

|---|---|---|---|

| Graphite | 16 /40 /80 | 1400kg/h | SYXZ-1000-3S |

| Calcium Powder | 120~180 | 5000kg/h | SYXZ-1500-2S |

| Oil Fracturing Proppant | 30 /80 | 10000kg/h | SYXZ-1500-2S |

| Quartz Powder | 100 | 480kg/h | SYXZ-1000-3S |

| Suar Powder | 24 | 1500kg/h | SYXZ-1000-1S |

| Emery | 2.2mm | 600kg/h | SYXZ-800-3S |

| Chinese medicine powder | 80 | 550kg/h | SYXZ-800-1S |

| Pollen | 12 | 100kg/h | SYXZ-400-1S |

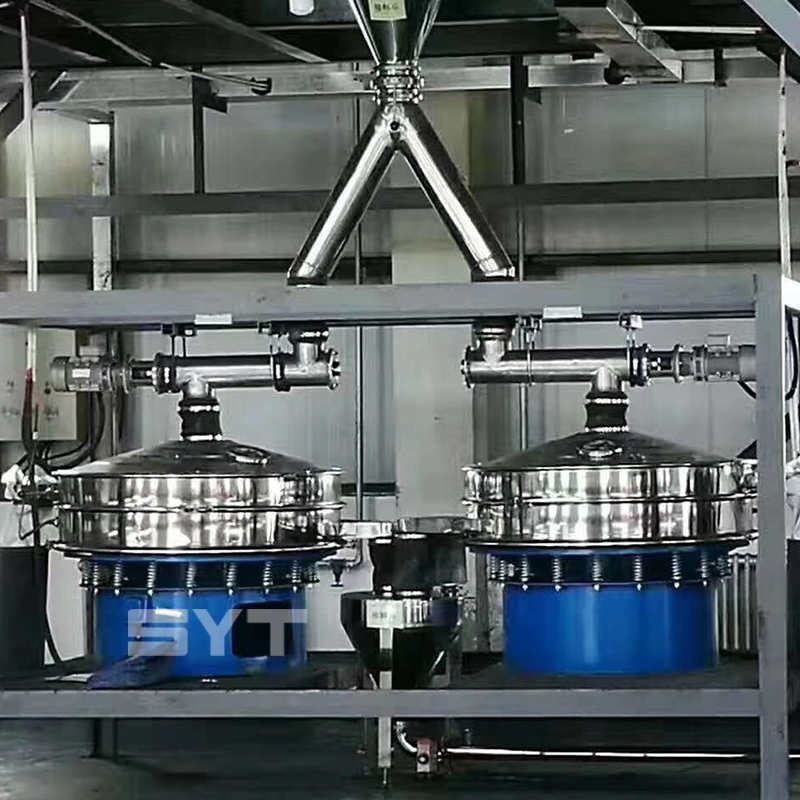

Customer Site

Powder Sieving Machine Manufacturer

Sanyuantang is a well-known manufacturer of powder sieving machine and other screening equipment in China.

We can provide customized powder screening machine service. Include technical support and corresponding solutions based on your production requirements, material characteristics, output, etc. Whether it is for special material characteristics, need to match a specific production line or process, or require equipment of specific sizes and specifications, we can customize the design and manufacturing according to your needs.

Want to learn more about how to customize a powder screening machine to fit your workflow? Please contact us and we will try our best to help you.