Circular Tumbler Screen for Rubber Industry Screening

In the rubber industry, a circular tumbler screen is commonly used in the screening process of rubber particles. The tumbler screen realizes the separation of particles through vibrating screen mesh, and the aperture size of the screen mesh can be adjusted according to the need to meet the screening requirements of different particle sizes.

Tumbler Screen for Rubber Industry Solutions

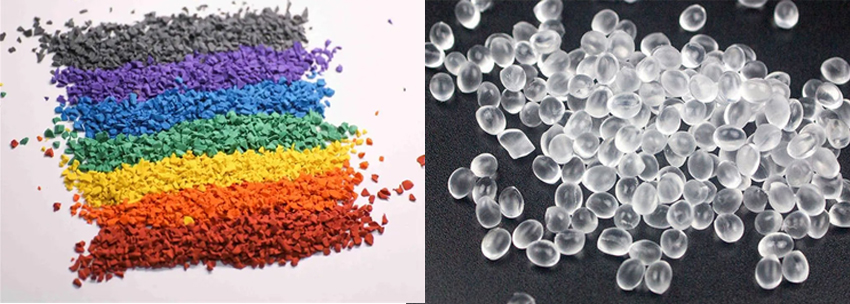

Recently, our company has received a lot of vibrating screen demands from rubber industry customers, such as neoprene rubber (CR), butadiene rubber (BR), natural rubber (NR), butyl rubber (IIR), heteroprene rubber (IR), nitrile butadiene rubber (NBR), fluorine rubber (FKM), ethylene propylene diene rubber (EPDM). They all belong to rubber powder and have some of the same characteristics, they also have different characteristics, and our company recommends the most suitable vibrating sieve machine for customers according to their mesh size, production capacity, and material properties.

The customer’s demand is 500kg-600kg per hour, and the screen mesh required is 26 mesh-40 mesh-60 mesh. Because the specific gravity of rubber powder is small and it is a kind of elastic material, the preferred solution is the tumbler screening machine, and then according to the customer’s mesh requirement, output requirement, and land requirement, we recommend using 1600mm diameter, three-deck tumbler screen.

Tumbler Screen Features

Tumbler screening machine has the advantages of high screening efficiency, high screening precision, easy operation, easy maintenance, and so on. It can be used in different screening stages such as primary screening, intermediate screening, and fine screening. For the rubber industry, circular tumbler screener can be used for the preliminary screening of rubber particles, separating particles of different sizes to ensure the quality of the product and meet the production requirements.

After the communication between our engineers and the production workshop, we determined the swing width and running track of the tumbler screen, and then tested the machine, and delivered it to the customer.

After a few days of experiment by the customer, the output can reach 800 kilograms per hour. The capacity is significantly increased. It also greatly reduces the labor cost.

If you are screening rubber foam-related products, please contact us. As a professional tumbler screen manufacturer and supplier, Sanyuantang Machine has 30 years of experience in producing and designing. we will be happy to provide you with suitable solutions. We are also sure to provide perfect service to the users of our products. Spare parts are supplied on time to ensure the trouble-free operation of customers’ machines.

Note:

When using the tumbler sieve, you need to pay attention to setting the appropriate vibration frequency and amplitude and the size of the screen mesh aperture to ensure the screening effect and throughput control. At the same time, regular cleaning of the screen mesh and checking the operating condition of the equipment are also an important link to ensure screening efficiency and product quality.