Round vibrating screen also called a circular vibrating screen, with a circular appearance, is a kind of high-precision fine powder screening equipment, which can be used for screening and filtering granules, powder, mucus, and other materials. It is widely used in food, medicine, chemical, metallurgical powder, paint, ceramic slurry, and other industries.

Round vibrating screens in the material can be divided into the following three types: stainless steel vibrating screen, carbon steel vibrating screen, and corrosion Plastic PP vibrating screen.

Carbon Steel Vibrating Screen

Standard Round Vibrating Screen

Full Steel Stainless

Anti Corrosion Plastic PP

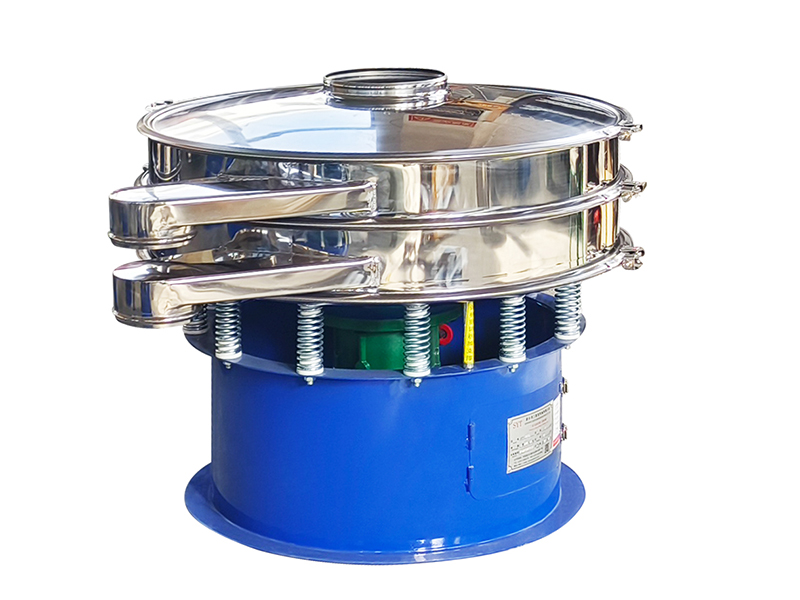

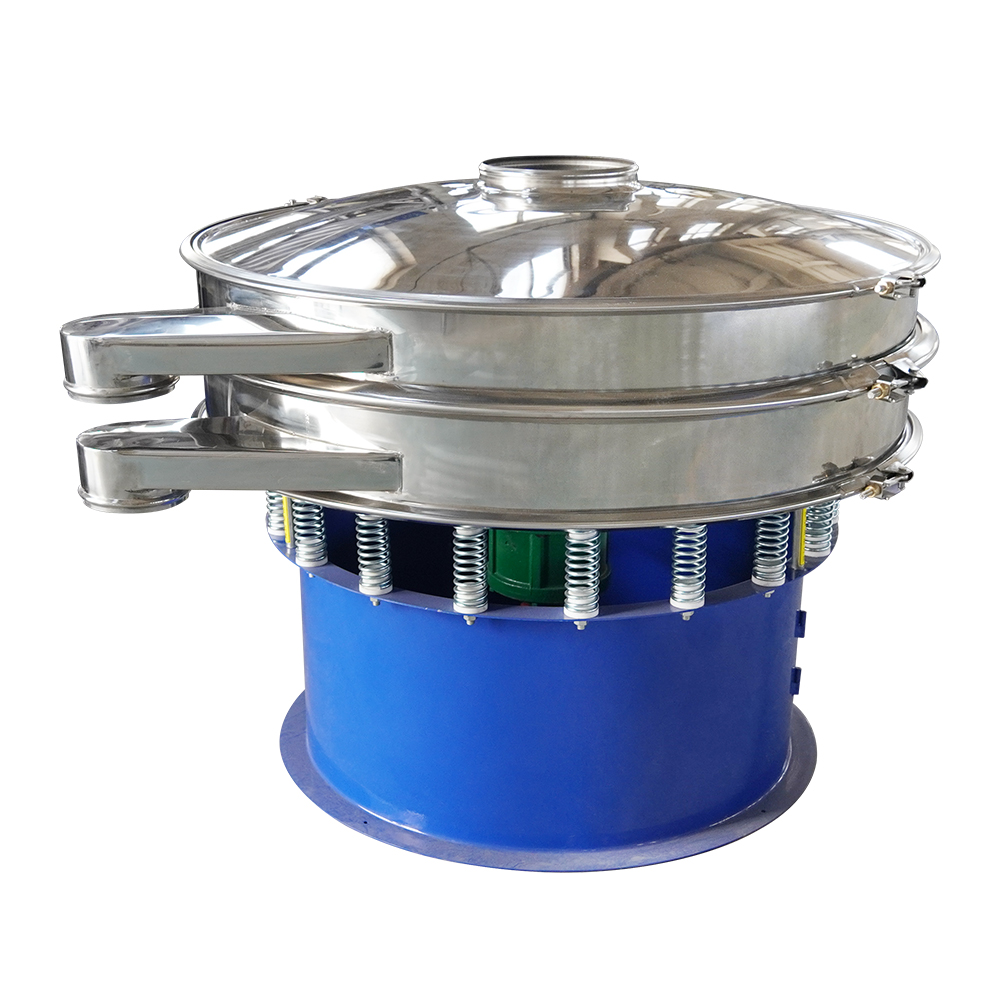

1. Standard Round Vibrating Screen

Standard round vibrating screen, the screen body frame is made of stainless steel, and the base is made of carbon steel. The stainless steel frame provides corrosion resistance and high strength, while the carbon steel base provides stable support.

This design can handle various types of materials and environments. Mainly used for screening particles, powders, etc. The smallest sieving is 500 mesh or 0.028mm, and the smallest filtration is 5 microns.

Grading and screening, it can screen one to five layers of mesh, and can perform two to six levels of sorting or filtration at the same time, with a grading accuracy of over 98%.

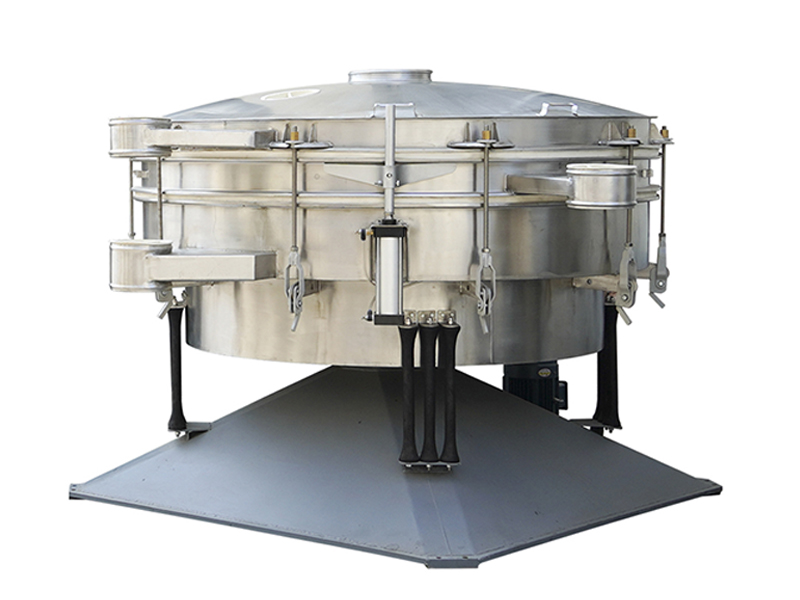

2. Full Stainless Steel Vibrating Screen

Stainless steel vibrating screens are commonly used for screening and filtering powders, granules, liquids, and other materials.

They are commonly used in food processing, chemical, pharmaceutical, and other industries. Stainless steel vibrating screens are rugged and easy to clean and maintain for food-grade and pharmaceutical-grade applications.

3. Carbon Steel Vibrating Screen

Carbon steel rotary vibrating screens offer durability and corrosion resistance and are commonly used in demanding industrial applications such as pharmaceutical, food processing, and chemical processing.

4. Anti Corrosion Plastic PP Polypropylene Vibrating Screen

The Anti Corrosion Plastic PP Polypropylene Vibrating Screen completely adopts non-metallic materials from the screen frame, screen, and cleaning device, which eliminates the problem that some special materials will produce chemical reactions in contact with metal. It’s the current effective solution to the oxidation, corrosion of steel material screening, impurity removal, and filtering program, and ensures that the material in the screening process will not deteriorate.

Working Principle

The working principle of round vibrating screen is made of the vertical motor as the excitation source, and there are eccentric hammers installed at the upper and lower ends of the motor, which transforms the rotary motion of the motor into three-dimensional horizontal, vertical, and inclined motion, and then transmits this motion to the screen surface.

Adjusting the phase angle of the upper and lower ends can change the trajectory of the material on the screen surface, because its vibration principle of operation is also known as the “three-dimensional vibration screening filter”.

Round Vibrating Screen Parameters

| Model | Effective diameter | Screen size | Layer | 0.25 kW |

|---|---|---|---|---|

| SY-400 | 380 mm | 2-500 mesh | 1-3 layers | 0.55 kW |

| SY-600 | 580 mm | 1-3 layers | 0.75 kW | |

| SY-800 | 780 mm | 1-4 layers | 1.1 kW | |

| SY-1000 | 970 mm | 1-4 layers | 1.5 kW | |

| SY-1200 | 1170 mm | 1-5 layers | 2.2 kW | |

| SY-1500 | 1470 mm | 1-5 layers | 3 kW | |

| SY-1800 | 1770 mm | 1-5 layers | 3 kw |

Features

- Wide application: essence and mucus can be sieved, 1-5 layers of screen mesh filtration, sieving range is 5~500 mesh.

- Unique mesh frame design, easy to change the mesh (only 3-5 minutes), simple operation, easy to clean.

- Fully sealed structure can ensure that the mesh is not blocked and the powder does not fly.

- Discharge port can be adjusted 360 arbitrarily, impurities, coarse material automatically discharged, 24 hours continuous operation.

- Portable design, small size, space-saving, easy to move.

- It can be designed according to the user’s demand, such as adding edge type, gate type, powerful type, sealed type, etc.

Application of Round Vibrating Screen

- Chemical industry: resin, paint, pigment, rubber, carbon black, activated carbon, co-solvent, glue powder, yuanming powder, polyethylene powder, quartz sand, and so on.

- Medicine: Chinese medicine powder, western medicine powder, medicine raw material powder, etc.

- Foodstuffs: sugar, salt, monosodium glutamate, starch, milk powder, soybean milk, rice flour, dehydrated vegetables, fruit juice, fish meal, food additives, and so on.

- Kiln industry: glass, ceramics, porcelain slurry, grinding materials, refractory bricks, kaolin lime, mica, alumina, calcium carbonate, and so on.

- Metal metallurgy: lead powder, zinc oxide, titanium oxide, casting sand, adamantine powder, aluminum powder, iron powder, various metal powders, etc.

Custom Round Vibrating Screen

We can customize different types of vibrating screens according to your requirements and offer competitive prices. If you want to know more about vibrating screening equipment, please contact us.

Add hopper

Add scraper

Extended feed port

Open type

Round Vibrating Screen Manufacturer

Sanyuantang Machine is a professional manufacturer and factory of round vibrating screens in China. we have excellence in manufacturing technology and innovative manufacturing concepts, the company has increased and become one of the production bases of vibration machinery in China.

FAQs

Learn more About

round vibrating screen

Read our blogs, to help you learn more about round vibrating screens.